Everything You Need to Know About Mesh Fabrics

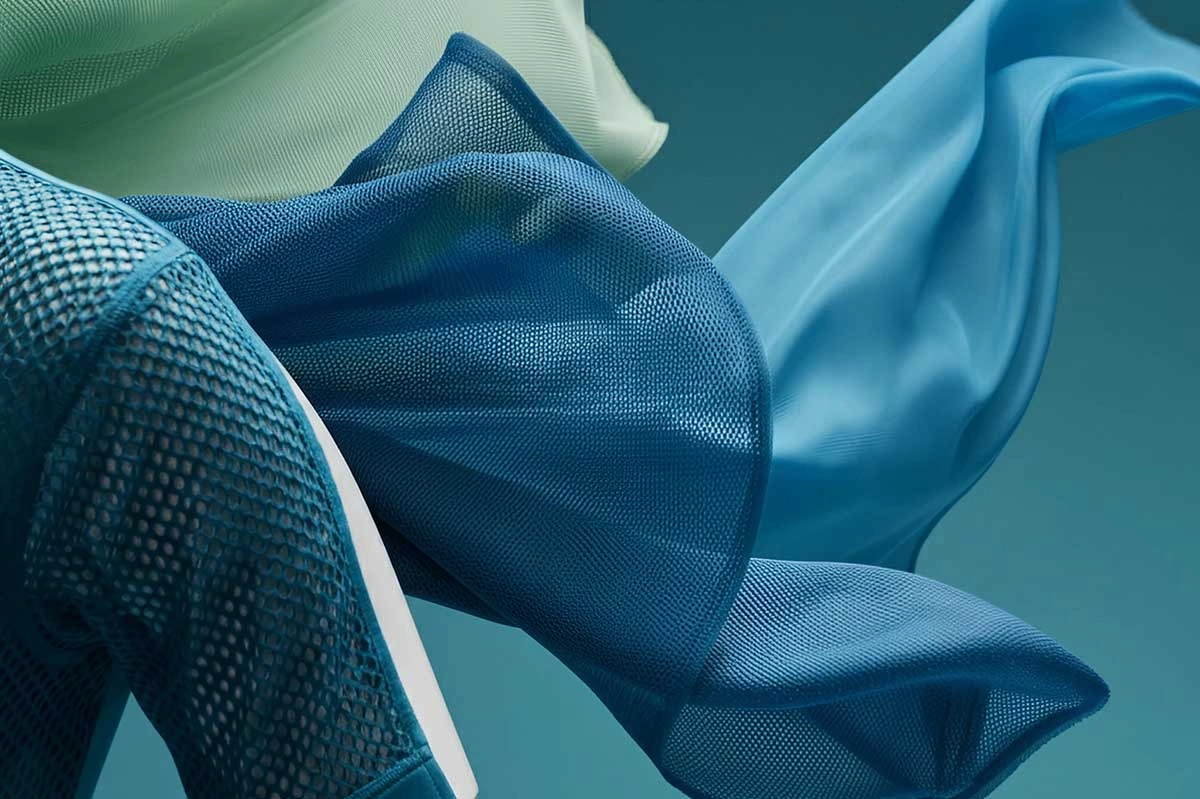

Mesh fabrics have steadily emerged as a staple in various industries, from high-fashion garments to cutting-edge medical textiles. Known for their versatility, breathability, and performance-enhancing qualities, they hold a prominent place in the textile and garment manufacturing industry.

This comprehensive guide covers everything about mesh fabrics—from their materials and construction techniques to their types, applications, and emerging trends. If you’re a garment manufacturer, textile trader, or wholesaler, this post will give you the insights you need to integrate mesh fabrics into your portfolio.

What Are Mesh Fabrics?

At its core, mesh fabric is a textile with an open-weave structure, creating a net-like appearance. This construction makes it distinctively lightweight, airy, and durable. Its design allows air to pass through the material, making it an ideal choice for applications that require breathability, flexibility, and comfort.

There are a few different types of mesh fabrics, each with unique characteristics and applications. These types include polyester mesh, known for its durability, and power mesh, which offers excellent stretch and support. Mesh fabrics stand out because of their practical benefits and aesthetic appeal, offering functionality and performance with modern design versatility.

History and Production of Mesh Fabric

Mesh fabric has a rich history that dates back thousands of years. The concept of mesh fabric was first explored in the late 19th century by Lewis Haslam, a textile innovator who founded the textile company Aertex. Haslam was inspired by his aunt’s gloves with holes, which kept her hands warm, and he developed the first mesh fabric for use in clothing. Initially, mesh fabric was used by soldiers in the trenches, but it later became popular in athletic wear, particularly in the mid-1980s.

The production of mesh fabric involves refining petroleum oil to extract polyamide monomers, which are then reacted with acid to form polyamide or polyester. The resulting polymers are melted and forced through spinnerets to create polymer strands. These strands are then packed onto spools and shipped to textile manufacturing facilities to be woven into mesh fabric. The production process can vary depending on the type of fiber used, with polyester and nylon being the most common.

Materials Used in Polyester Mesh Fabrics

Mesh fabrics can be made using different types of fibers, each offering unique properties based on the material chosen.

-

Polyester

Polyester mesh fabric is widely used due to its durability, lightweight nature, and ability to resist wrinkles and stains. It offers excellent structural stability, making it perfect for applications like sportswear and industrial uses. Polyester or nylon fibers are commonly used in mesh fabric production.

-

Nylon

Known for its exceptional strength and elasticity, nylon mesh fabric is often chosen for performance clothing, bags, and netting due to its stretch and abrasion resistance. The production process of nylon fibers involves refining petroleum oil to extract polyamide monomers, which are then polymerized and spun into long strands before being woven into various mesh fabric styles.

Fabrics that incorporate elastane or spandex give mesh fabrics stretch capabilities. These are ideal for creating snug-fitting garments like leggings, athletic apparel, and shapewear.

-

Recycled Polyester

Sustainable fashion brands increasingly turn to fabricated mesh material made from recycled plastics. Not only is recycled polyester environmentally friendly, but it also retains all the resilient properties of traditional polyester.

Other fibers, such as cotton and rayon blends, are sometimes used to create soft mesh fabric with enhanced comfort for certain applications like casual wear or medical textiles.

How Are Mesh Fabrics Made?

Mesh fabrics are primarily produced through knitting or weaving methods. Different mesh fabric variants, such as polyester, nylon, and power mesh, are produced using similar processes.

-

Knitted Mesh Fabric

Knitting creates a more elastic, flexible mesh fabric that can stretch. Lightweight garments and sportswear often rely on knitted mesh fabric for its comfort and adaptability.

-

Woven Mesh Fabric

Woven mesh fabrics are less stretchy but stronger and more structured. These fabrics are chosen for applications that require durability, like industrial textiles or heavy-duty bags.

The process involves adjusting yarn size, knit density, and thread tension to achieve the desired characteristics, such as breathability, stretch, and softness. Multiple terms can refer to the same mesh fabric variant, highlighting the complexity of mesh fabrics.

Types of Nylon Mesh Fabrics and Their Features

There are multiple types of mesh fabrics on the market, each suited to specific needs.

As the name suggests, this fabric focuses on allowing airflow, making it essential for applications like sportswear and casual apparel.

These designs integrate a waterproof layer, ideal for outdoor gear, tents, and industrial uses.

A delicate and lightweight variant often utilized in intimate apparel, medical garments, and stylish applications requiring comfort.

-

Stretch Mesh Fabric

Ideal for athletic wear and fitted garments. Its balanced elasticity provides unrestricted movement and form-fitting comfort. Stretch mesh fabric is also used in shaping apparel due to its elasticity.

-

Knitted Mesh Fabric

Known for its flexibility and stretch, common in activewear and other functional uses.

-

Power Mesh

Power mesh is recognized for its compression abilities and is frequently utilized in sportswear and shapewear garments. This type of mesh fabric is distinct from regular nylon or polyester mesh due to its increased elasticity and sheer appearance. Power mesh is also occasionally applied in home decor.

Understanding these types helps garment manufacturers and textile traders identify the mesh fabric material that matches their production requirements.

The Unique Features of Mesh Fabrics

Mesh fabrics are revered for their distinctive combination of qualities, including:

-

Breathability

The porous construction ensures excellent airflow, preventing overheating. Additionally, polyester mesh fabrics can wick moisture away from the body, enhancing comfort during physical activities.

-

Lightweight

With its open-weave structure, mesh fabric is remarkably light, making it suitable for performance-focused applications.

-

Durability

Despite being lightweight, mesh fabrics demonstrate excellent tensile strength, especially polyester mesh fabric or nylon-based materials.

-

Flexibility

Stretch mesh fabrics add unmatched versatility for activewear and fitted applications.

Applications of Mesh Fabrics

Mesh fabrics are incredibly versatile, with applications spanning industries.

Sports and Activewear: Shaping Apparel

Breathable mesh fabrics are a go-to for athletic equipment and clothing. Highlights a high-end sportswear company integrating stretch mesh fabric in its apparel, increasing comfort and customer satisfaction while boosting sales.

Sustainable Fashion

Recycled polyester mesh fabrics offer an eco-friendly solution for brands like [Brand Name], which are eliminating traditional fabric footprints. How a sustainable fashion brand achieved high consumer engagement with eco-friendly mesh designs.

Medical Textiles

Soft mesh fabrics find extensive use in healthcare. Lightweight, antibacterial designs help improve patient comfort in surgical gowns and medical equipment.

Everyday Style

Mesh clothing fabric has made its mark in fashion, seen in trendy dresses, tops, and even accessories.

Industrial Applications

Durable woven varieties are employed in heavy-duty applications like netting, seat covers, safety vests, and more. Nylon mesh is also commonly used in making tent screens, showcasing its versatility in outdoor equipment. Additionally, mesh fabric is practical for everyday items such as laundry bags, emphasizing its functional aspects in various applications.

Environmental Impact and Sustainability

The environmental impact of mesh fabric depends on the materials used in its production. Most mesh fabrics are made from synthetic materials such as polyester and nylon, which have a negative impact on the environment. The production of nylon requires adipic acid, which releases nitrous oxide into the atmosphere, while the production of polyester requires large volumes of water, which is then contaminated and reenters the hydrosphere. Additionally, neither polyester nor nylon biodegrade, which means that garments made from these fabrics can continue to harm the environment for thousands or millions of years.

However, there are efforts to make mesh fabric more sustainable. Some textile companies are using recycled materials to produce mesh fabric, which reduces the amount of waste generated during production. Additionally, some mesh fabrics are designed to be biodegradable, using natural fibers such as cotton or hemp. Consumers can also play a role in reducing the environmental impact of mesh fabric by choosing sustainable options, recycling old mesh garments, and properly disposing of mesh fabric waste.

Care and Maintenance of Mesh Fabrics

Mesh fabrics require delicate care to maintain their quality and longevity. Follow these tips for upkeep:

-

Gentle Washing

Hand wash mesh clothing fabric or put it in a laundry net for machine washes to avoid damage.

-

Use Mild Detergent

Harsh chemicals can degrade the fibers over time, so use mild and non-bleach detergents.

-

Air Dry

Avoid tumble drying as the heat can weaken synthetic fibers like nylon or polyester. Hang the fabric to dry naturally.

-

Avoid Heavy Pressing

Mesh fabrics typically don’t require ironing. If necessary, use a low-heat setting.

Certifications and Compliance

There are several certifications and compliance standards that mesh fabric manufacturers can adhere to in order to ensure the quality and sustainability of their products. The Global Recycle Standard (GRS) is a certification offered for mesh fabric made from 100% recycled materials. The International Organization for Standardization (ISO) provides a certification for mesh fabric that meets certain quality standards. The American National Standards Institute (ANSI) provides certification that integrates ISO requirements and lays down additional standardization principles.

Mesh fabric manufacturers can also comply with regulations such as the Occupational Safety and Health Administration (OSHA) standards for workplace safety and the Environmental Protection Agency (EPA) regulations for environmental sustainability. Additionally, some mesh fabric manufacturers may choose to comply with industry-specific standards, such as the American Society for Testing and Materials (ASTM) standards for textile testing.

By adhering to these certifications and compliance standards, mesh fabric manufacturers can ensure that their products meet the highest standards of quality, sustainability, and safety.

Current Trends in Mesh Fabrics

The textile industry is seeing exciting innovations in mesh fabric usage.

-

Sustainable Options

Focus has shifted to recycled and biodegradable fabric mesh material, reflecting consumer demand for eco-conscious products. Historically, the textile company called Aertex pioneered mesh fabrics, being the world's first producer of mesh fabric and influencing the apparel industry, particularly in athletic wear through collaborations with brands like Adidas.

-

Hybrid Fabrics

Manufacturers are exploring combinations of mesh fabric and other materials for added versatility.

-

Functional Enhancements

Advances in knitting technology are enabling mesh fabrics to feature waterproof or antibacterial properties unobtainable in the past.

The Role of Mesh Fabrics in Textile Manufacturing Facilities

Mesh fabrics have cemented their place as a dynamic, multifaceted textile across industries. From enhancing athletic performance with stretch mesh fabric to providing comfort in medical textiles, their utility is virtually unparalleled. Following the trends and understanding fabric properties will give garment manufacturers and textile traders an edge in expanding their offerings.

By considering the material compositions, applications, and care recommendations outlined here, businesses can select the perfect mesh fabric to suit their production needs, whether it’s breathable sportswear, durable industrial materials, or delicate fashion-forward garments.

For expert advice on sourcing or using mesh fabrics, reach out to [Your Company Name], your trusted partner in textiles.

Resources Page

- Mesh Material for Outdoor Furniture: The Ultimate Guide for Manufacturers

- The Perfect Fabric for Outdoor Gear Manufacturers: Vinyl Mesh

- Fishnet Fabric by the Yard for Outdoor Gear Manufacturers

- You Need to Know About Mesh Fabric Roll

- Foam Mesh Fabric: A Comprehensive Guide

- A Comprehensive Guide to Large Mesh Fabric for Industry Professionals