Material: Corespun poly poly

Count: 20s/2

Length per cone: 4000m

Logo: MH brand or as customers' request

Color: We offer a wide variety of colours to choose from.

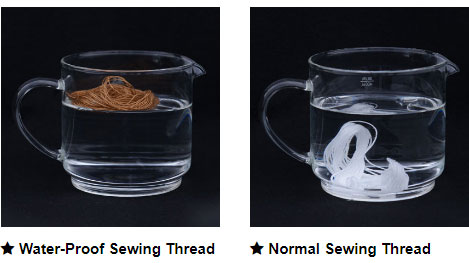

Feature: It has a special water-resistant finish which inhibits the capillary effect, thereby ensuring that no water is taken up by the thread. When the correct sewing tension is used, the transport of water through the needle hole is prevented.

Water-proof effect can be used for spun polyester sewing thread, poly/poly core sewing thread.

Application: It is a popular thread for specialty applications, like outdoor wear, raincoats, umbrellas, shoes and boots, sailing gear, life jackets, heavy duty awning and tent sewing.

Product Features

- High waterproof performance

- Gentle luster

- Excellent seam strength appearance

- High productivity

- Extensive color range

- High chemical resistance

Sewing Thread Quality Guarantee

- Yarn Count

- Twist per unit length

- Single yarn strength

- Evenness

- Hairiness

- Automatic color control system

- Fongs dye machine

- Thies pressire dryer

- SSM automatic winder machine

- Automatic packing machine

- Strength

- Elongation

- Colour fastness

- Sewing Performance

- Packing

Product details

Our products include various kinds of threads, like spun polyester sewing thread, corespun polyester sewing thread, eco-friendly recycled polyester sewing thread, waterproof sewing thread, anti-UV sewing thread, cotton sewing thread, nylon bonded thread, embroidery thread, polyester textured yarn, metallic yarn, fishing twine, etc. available in different sizes and specifications to meet all customers' needs.

Color card

Application

Certificate:

OEKO-TEX standard 100 Annex 6 Class 1

Factory:

MH has three industry zones for thread factories, with 220,000m2 plant area and 1100 workers, equipped with high-standard machines and strict manufacturing management system

With annual producing capacity 30000+ tons, that means about 2000x40'HQ per year.

Automatic Dispensing System: Low chromatic aberration, high level of color fastness

Dyeing and Drying: During dyeing and drying process, we not only care about color matching and color fastness, also we care about dyed yarn spindle shape which will effect thread rewinding quality. As the suitable yarn spindle shape will reduce the breakage rate during rewinding.

Sewage Treatment Center: Green manufacturing, the advanced sewage treatment center and water recycling system are committed to acting in energy saving, environmental protection.

SSM TK2-20CT High-speed Precision Winding Machines: Not only ensure the thread cone in good shape with suitable tension, and has no deformation during transportation, but also has an excellent performance in length and oil uniformity.

Automatic Packaging Machine: it keeps the sewing thread in nice and neat shape, and the sticker will be exactly in the same place without slanting

About Ningbo MH

Ningbo MH was established in 1999, specialized in garment accessories and tailoring materials.

At present, MH owns nine factories located in 3 industry zones, with 382,000m2 plant area and 1900 workers, producing polyester sewing thread, embroidery thread, lace and embroidery, ribbon & tape.

MH also set up long-term cooperation with 1500 manufacturers for 10000 different kinds of tailor's material and fabric.

MH has certificates of ISO 9001:2015, ISO14001:2015, ISO18001:2007