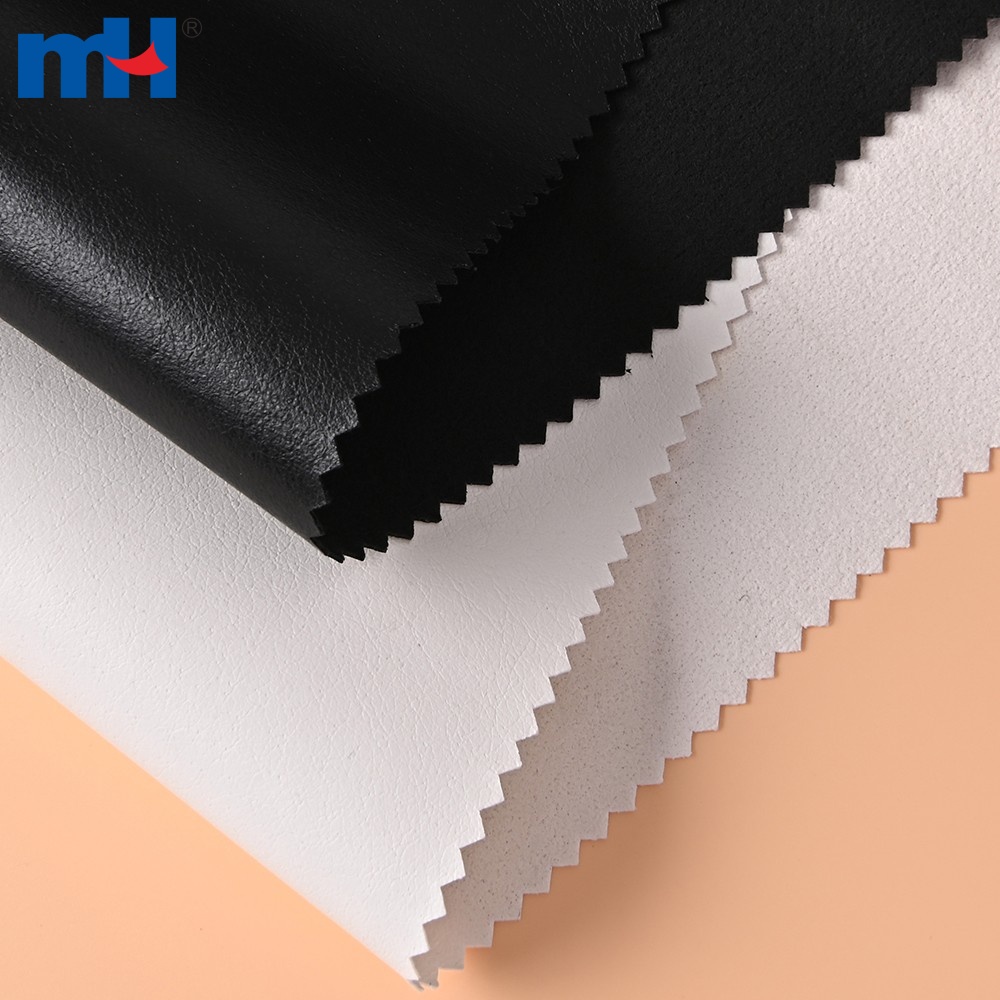

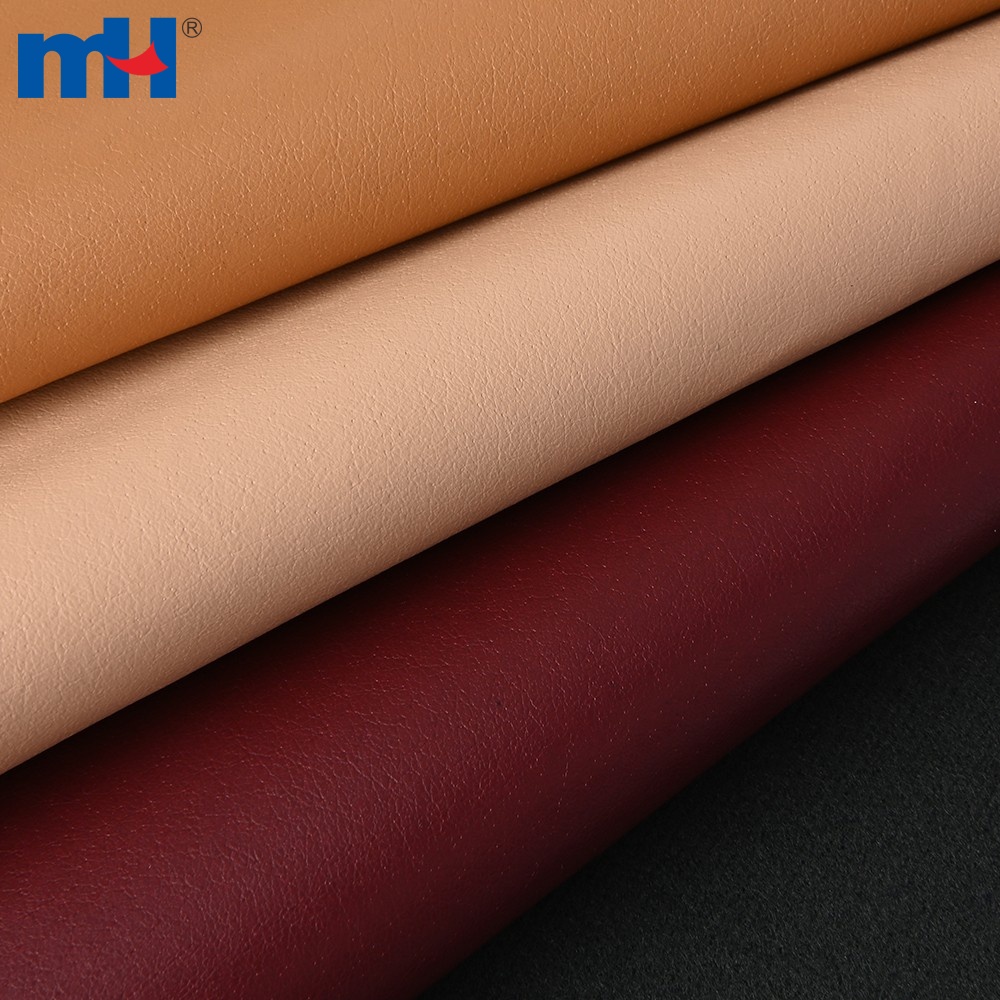

0.55mm 45 Inches Dry-Laminated Leather Lining Fabric for Shoes

Dry-Laminated Leather Lining Fabric for Shoes

Price: Quote as custom

- Material: PU+Imitation Cotton Fleece Backing

- Thickness: 0.55m

- Width: 54 inches

- Features: Dry-Laminated

◆ Lead Time: 25-35 days

◆ Shipping: Sea freight, Railway freight

◆ Payment: T/T, L/C ...

Material: PU+Imitation Cotton Fleece Backing

Thickness: 0.55m

Width: 54 inches

Features: Dry-Laminated

What's the difference between Dry and Wet Laminated Process?

The differences between dry - laminated PU shoe lining leather and wet - laminated PU shoe lining leather are mainly reflected in the following aspects:

Process Principles

- Dry - laminated PU shoe lining leather: It mainly relies on heating and applying pressure to closely bond the PU shoe lining leather with the underlying material. The lamination process does not rely on a large amount of glue solvents.

- Wet - laminated PU shoe lining leather: Usually, an appropriate amount of solvent is added to the PU resin, which is then coated on the base fabric. Subsequently, through processes such as drying, the solvent volatilizes and the PU resin solidifies to form the leather. During the lamination process, glue or other adhesives are required.

Material Characteristics

- Breathability:

- Dry - laminated PU shoe lining leather: Due to the characteristics of its production process, its breathability is relatively poor.

- Wet - laminated PU shoe lining leather: The synthetic leather produced has good moisture - permeability and breathability. It has a soft, plump, and light - weight handfeel, and is more reminiscent of the style and appearance of natural leather.

- Softness and Handfeel:

- Dry - laminated PU shoe lining leather: The handfeel is relatively stiff, and its softness is inferior to that of wet - laminated PU shoe lining leather.

- Wet - laminated PU shoe lining leather: It has better softness and plumpness, and the handfeel is closer to that of natural leather.

- Strength and Durability:

- Dry - laminated PU shoe lining leather: The synthetic leather produced has excellent strength, a firm bond, good strength and durability, and is less prone to problems such as delamination and shedding.

- Wet - laminated PU shoe lining leather: Its strength and durability are relatively weak, and it is easily affected by external factors such as friction and humidity, and may experience wear, cracking, etc.

Production Efficiency and Cost

- Production Efficiency:

- Dry - laminated PU shoe lining leather: The dry - lamination process is relatively simple. There is no need to wait for the glue to dry, etc., so the production efficiency is high, making it suitable for large - scale production.

- Wet - laminated PU shoe lining leather: The wet - lamination process requires multiple steps such as coating and drying, and the production process is relatively complex, resulting in lower production efficiency.

- Production Cost:

- Dry - laminated PU shoe lining leather: Since it does not require the use of a large amount of glue and solvents, the production cost is relatively low.

- Wet - laminated PU shoe lining leather: The use of glue and solvents, as well as multiple drying treatments, leads to a relatively high production cost.

Environmental Friendliness

- Dry - laminated PU shoe lining leather: During the lamination process, it does not use a large amount of glue solvents, reducing the volatilization and emission of organic solvents, causing less pollution to the environment, and is more environmentally friendly.

- Wet - laminated PU shoe lining leather: The glue and solvents used may contain harmful substances such as volatile organic compounds (VOCs), which can cause certain pollution to the environment during the production process.

Appearance Quality

- Flatness:

- Dry - laminated PU shoe lining leather: The dry - lamination process can closely adhere to the underlying material. It is not easy to have problems such as air bubbles and wrinkles, so the product has good flatness.

- Wet - laminated PU shoe lining leather: If the glue is not evenly coated or the drying is insufficient, air bubbles, wrinkles and other defects may occur between the PU shoe lining leather and the underlying material, affecting the appearance quality of the product.

- Patterns and Colors:

- Dry - laminated PU shoe lining leather: The patterns and colors are relatively uniform, and there will be no problems, such as blurred patterns or color changes caused by glue penetration.

- Wet - laminated PU shoe lining leather: Sometimes, due to the influence of the glue, the uniformity of the patterns and colors may be damaged to a certain extent.

About Ningbo MH

MH specializes in garment accessories and fabrics, offering high-quality solutions for the textile and home décor industries. With advanced automated warehousing, MH ensures efficient supply chain management and provides comprehensive after-sales support, exclusively serving businesses, not individuals.

1999

Since

871

Annual Sales

40

Branch Offices

600

Staffs