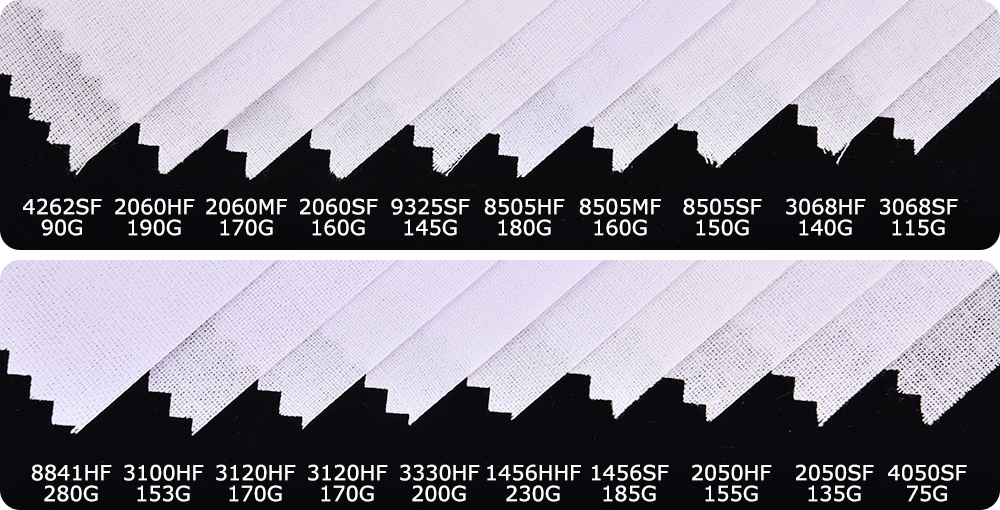

9325HF Shirt Collar Interlining Fabric

9325HF Cotton Shirt Collar Interlining

- Model6421-0047

MH Woven Interlining Factory

MH operates more than 40+ branches across 35 countries worldwide. We have a dedicated team of over 100 local staff who personally visit customers, ensuring seamless service delivery on behalf of MH. With just one call, or even without a call, as our staff regularly visit customers, our local team is always ready to provide assistance. Effective communication in the local language further enhances the smooth exchange of information, making it more convenient for everyone involved.

-

Direct-to-Client Services

Direct-to-Client Services -

Prompt Response without Time Zone Delays

Prompt Response without Time Zone Delays -

Effective Communication in Local Language

Effective Communication in Local Language

Customization Services

Composition Customization

Width Customization

Model Customization

Handfeel Customization

Glue Customization

Weight Customization

Product Description

| Name | Shirt Interlining Fabric |

| Model | 9325HF (Hard handfeel+fusible) |

| Material | 100% Cotton |

| Width | 90cm |

| Weight | 165g/㎡ |

| Specs | 20S*20S, 60*40 |

| Coating | HDPE |

| Color | White, Black, Grey, etc. |

| Temperature | 160-175℃ |

| Pressure | 3.0-3.5kg/c㎡ |

| Time | 15-20s |

| MOQ | 3000m/color |

| Delivery time | Within 25-30 days after receiving payment |

| Packing | 100m/roll |

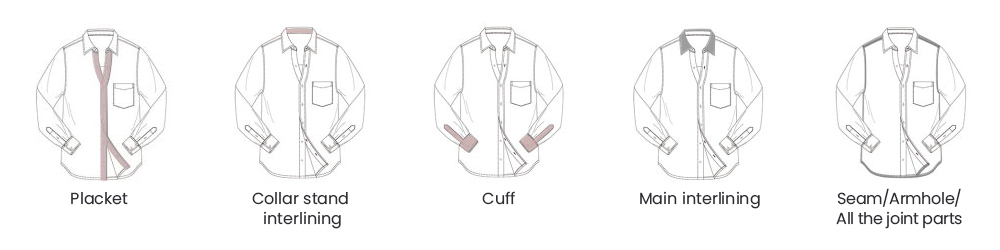

| usage | Shirt collar interlining is mainly used for men's and women's shirts, uniforms, Arab robes, hats (nurse hats) and other clothing collars, cuffs, plackets and etc. |

Using 100% cotton fabric as base fabric and coated with HDPE hot melt adhesive powder (according to different fabric requirements, choose different gluing methods and different quality grades of glue powder), mostly used on shirts.

It's cost-effective, and there is no MOQ requirement, the regular models have ready stock.

HF (hard feel) interlining is used for the collar and cuff of shirts, and SF (soft feel) interlining is used for the placket and the body of shirts.

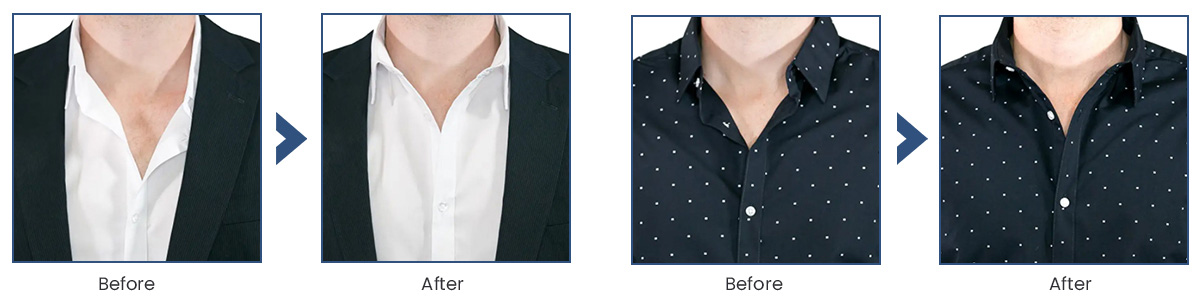

After ironing with the interlining, the shirt is crisp and stylish, and not easy to bubble or deform.

Interlining in Shirt

Fusing Conditions

| Tape |  Temperature (℃) |

Pressure |

Time |

Roller Press |

170℃±5℃ | 3±0.5kg/cm2 | 18±2 sec |

Flat Bed Press |

165℃±5℃ | 2.5±0.5kg/cm2 | 18±2 sec |

MH Collar Interlining Feature

About Ningbo MH

MH specializes in garment accessories and fabrics, offering high-quality solutions for the textile and home décor industries. With advanced automated warehousing, MH ensures efficient supply chain management and provides comprehensive after-sales support, exclusively serving businesses, not individuals.

Exhibition

Global Textile Excellence, Showcasing Worldwide.

MH at Leading Industry Exhibitions: Pioneering innovation, sustainability, and global collaboration.

Crafting the Future of Textiles—Join Us Across Continents.

Shipping Methods