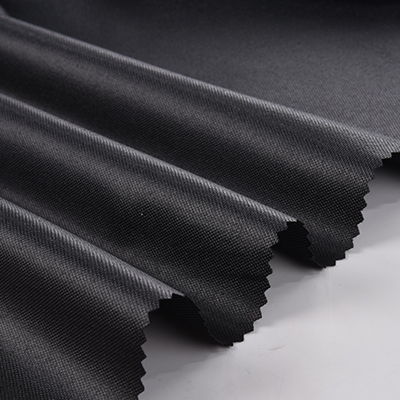

Tactical Vest Oxford Fabric Material for Military Tactical Vest

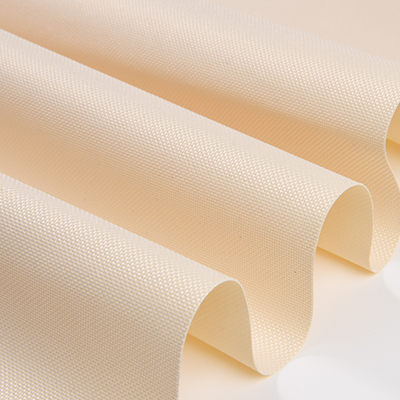

500D Nylon 66 Oxford Fabric

| Material: | 100% Nylon |

| Spec: | 500D, 82T |

| Weight: | 260g/m2 |

| Width: | 150cm |

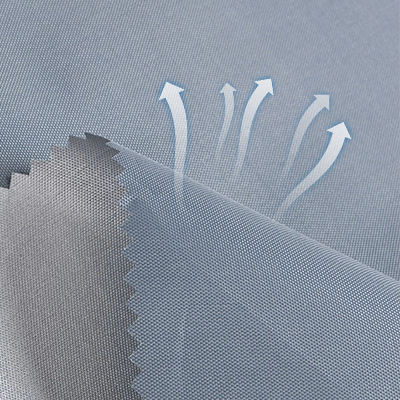

| Technology: | PU Coated |

| Color: | Color Card Available |

| Packaging: | 50m/roll |

| MOQ: |

|

| Certification: | OEKO-TEX® CERTIFIED  |

◆ Lead Time: 25-35 days

◆ Shipping: Sea freight, Railway freight

◆ Payment: T/T, L/C ...

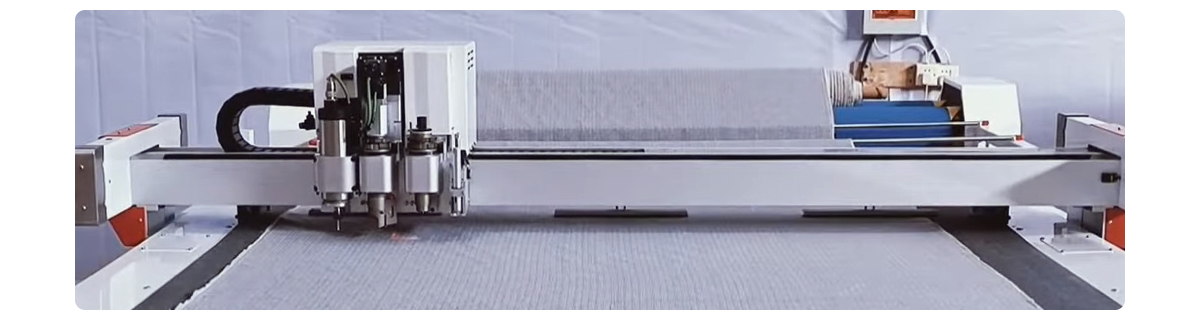

Woven Fabric Factory

About Ningbo MH

MH specializes in garment accessories and fabrics, offering high-quality solutions for the textile and home décor industries. With advanced automated warehousing, MH ensures efficient supply chain management and provides comprehensive after-sales support, exclusively serving businesses, not individuals.

Product Details

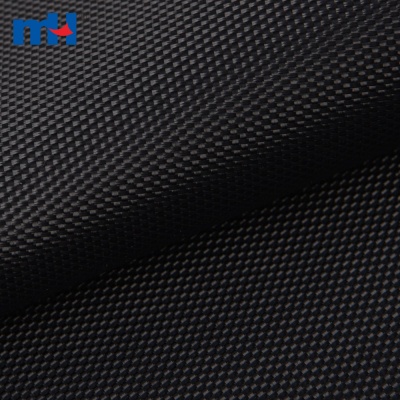

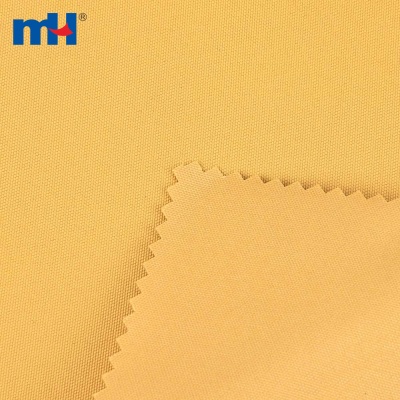

This fabric is 500x500 denier, 100% nylon, strong, durable, and waterproof.

Backing with a PU waterproof coating, making it extremely durable.

This oxford fabric is widely used for militaries such as tactical vests, backpacks, camping tents, holsters, and even for patio roofs, tents, canopies, duffle bags, awnings, makeshift roofs, outdoor umbrellas or even boat covers.

500D Brown Woven Oxford Fabric Test Report

1. Color Fastness to Perspiration ISO 105 E04:2013

| Unit: <Grade> | ||

| Acid | Alkali | |

| Color Change | 4-5 | 4-5 |

| Color Staining | ||

| Acetate | 4-5 | 4-5 |

| Cotton | 4-5 | 4-5 |

| Polyamide | 4-5 | 4-5 |

| Polyester | 4-5 | 4-5 |

| Acrylic | 4-5 | 4-5 |

| Wool | 4-5 | 4-5 |

2. Color Fastness to Rubbing ISO 105 X 12:2016

Dry: 4-5 Grade

Wet: 4-5 Grade

3. Color Fastness to Washing ISO 105 C06:2010 A2S

Wash at 40°C, wash time 30 minutes, with 4g/l ECE detergent solution, 1g/l sodium perborate tetrahydrate, 10 steel balls, SDC-DW multifiber adjacent fabrics.

Color Change: 4-5 Grade

Color Staining

Acetate: 4-5 Grade

Cotton: 4-5 Grade

Polyamide: 4-5 Grade

Polyester: 4-5 Grade

Acrylic: 4-5 Grade

Wool: 4-5 Grade

4. Color Fastness to Light ISO 105 B02:2014 Exposure method 3, using the blue wool reference 5.

Test Result: >5 Grade

5. Tensile Strength ISO 13934.1:2013 Strip Test

5cm strip test, CRE tensile test machine, testing speed 100mm/min, gauge length 200mm.

Breaking force: Warp 3000N, Weft 1800N

6. Tearing Strength ISO 13937.2:2000 Single-shaped method

CRE tensile test machine, testing speed 100mm/min, gauge length 100mm

Warp 160N, Weft 130N

7. Determination of resistance to surface wetting ISO 4920-2012

Spray test, the temperature of the used water is 20°C

Unit:<grade>

Specimen 1#: 4-5

Specimen 2#: 4-5

Specimen 3#: 4-5

Remark:

5–no sticking or wetting of the specimen

4– slight random sticking or wetting of the specimen face

3 – wetting of specimen face at spray points

2 – partial wetting of the specimen face beyond the spray points

1 – complete wetting of the entire specimen face beyond the spray points

0 – complete wetting of the entire face of the specimen

MH Oxford Fabric Feature

Customization Services

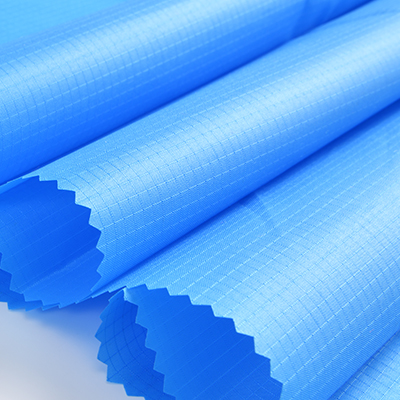

Material Customization

100% Polyester

100% nylon

Width Customization

Yarn Count Customization

Printing Customization

Technology Customization

Style Customization