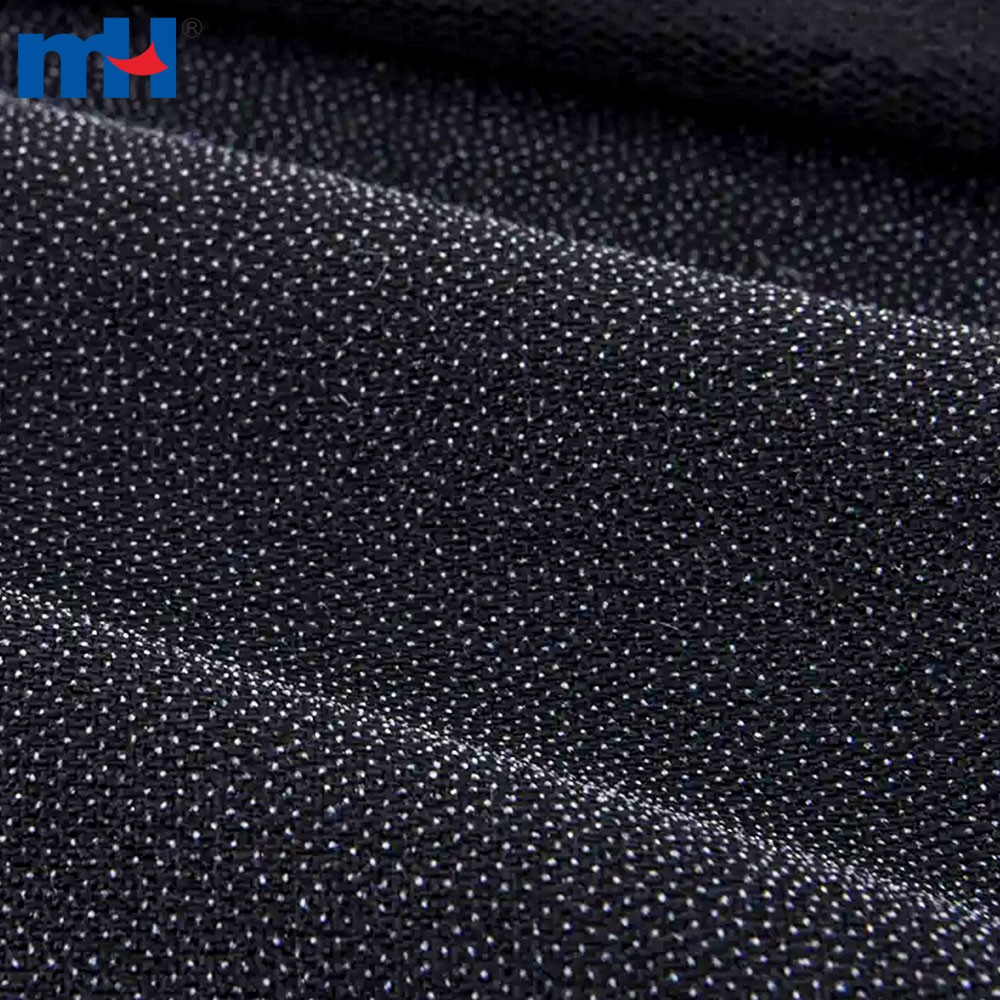

75D*300D Polyester Twill Woven Interlining Fabric

Twill Woven Fashion Fusing Interlining

- Model6424-1136

Main Features

| Model No. | 6424-1136 |

| Material | Polyester |

| Yarn count information | 75D*300D |

| Backing fabric process | Twill |

| Weight | 100GSM |

| Width | 150cm |

| Technics | Woven |

| Glue | PA+PES |

| Color | Black/White |

| Packing | 100m/roll,2rolls/bale (or as customer's requirement) |

Product Definition

Woven fashion fusing interlining belongs to the thicker specifications of woven fashion interlining, which is made of 75*300D polyester yarn, produced by a water jet loom with woven twill base fabric, and processed by double dot technology with the application of environmentally friendly PA and PES hot melt glue powder, the interlining base fabric is soft to the touch, thick, with good elasticity in warp and weft direction, the glue powder of coating is of excellent quality, and after bonding with the fabric, it does not back bleed, does not penetrate glue, does not release glue, and is easy to use.

Product Features

- The Woven fashion fusing interlining gram weight is high, soft feel, thick. Using PA and PES glue powder, double point bonding process, good bonding performance, high peel strength.

- Stable performance, shrinkage, heat shrinkage rate is small, after washing and hot pressing bonding size change should be very small, the appearance of flat, no wrinkles, no roll, no blistering, no degumming, and repeated washing, its performance remains unchanged.

- After pressing and dry cleaning, the appearance of color needs to be no change, not yellowing. The surface of the fabric and the lining should be free of glue and maintain a good feel, elasticity, and stiffness.

- After bonding with the fabric, the garment has good breathability, moisture permeability, water permeability, comfortable to wear.

- Has good sewability and shearability, cutting does not stain the blade, the piece of clothing cut near the non-stick, sewing time needle slide freely, not stain the machine needle eye.

Application

Collars, Cuffs, Pockets, And Other Detail Areas Of Garments

Packing: 50yds/roll

Our Company

Ningbo MH was established in 1999,specialized in garment accessories and tailoring materials. At present,MH owns nine factories located in 3 industry zones,with 382,000m2 plant area and 1900 workers, producing threads, fabrics, tapes, buttons, etc. MH also set up long-term cooperation with 1500 manufacturers for 10000 different kinds of tailor's material and fabric.

Factory

A fusible interlining is a thin layer made from woven, knitted or non-woven material bonded mechanically or thermally which when fused with fabric panel can give reinforcement, durability and can also stabilize and makes sewing work easier while sewing.

Certificate

MH has certificates of ISO 9001, ISO14001,ISO 45001 and OEKO-TEX 100 standard class 1