Stretch Materials in Textile Industry: All You Need to Know

Stretch fabrics have changed the textile industry, providing unlimited versatility and functionality for garment manufacturers, textile traders and home textile producers. From activewear and fashion garments to durable bedding and upholstery, the uses of stretch fabrics are as wide as the markets they serve. This blog will cover stretch materials, types, benefits, trends, challenges and sustainable options and will also share expert tips and real life examples.

By the end of this post you will have knowledge on stretch fabrics and how they can help you in your manufacturing or trading business.

What are Stretch Materials?

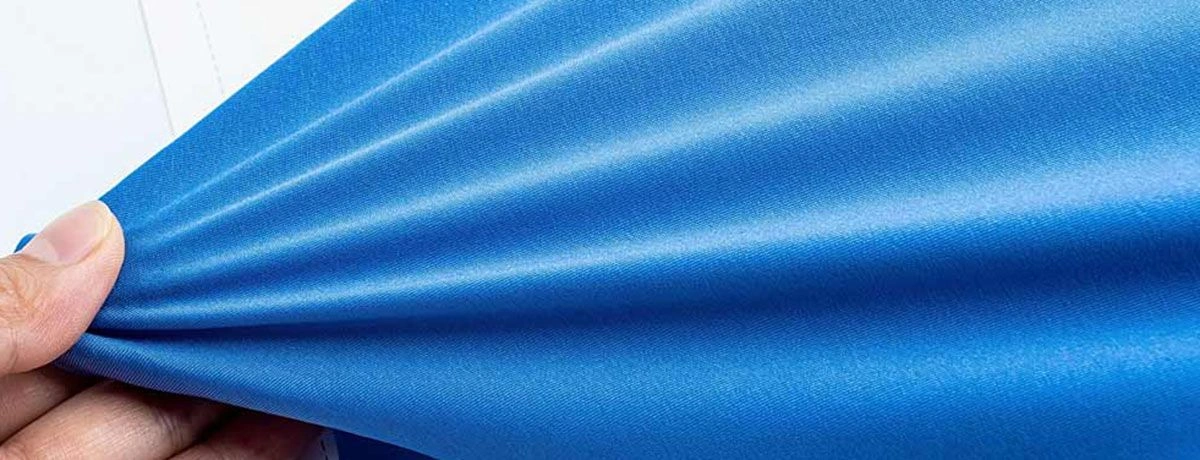

Stretch materials or stretch fabrics are textiles that can expand and recover their original shape when the tension is removed. This property is achieved by incorporating elastomeric fibers like spandex or elastane in the fabric structure, often blended with materials such as cotton fabric. Stretch materials are used to make clothing, home furnishings and industrial textiles where flexibility, comfort and durability is required.

These are used in:

-

Activewear for performance and mobility.

-

Casualwear like jeans and t-shirts for all-day comfort, making them ideal for everyday garments.

-

Home textiles like fitted sheets and stretchable upholstery.

-

Medical textiles like bandages and compression garments.

Characteristics of Elastic Material

Elastic materials are renowned for their remarkable ability to stretch and return to their original shape, making them indispensable in various applications. These materials, whether derived from natural or synthetic fibers, can be tailored to exhibit specific stretch properties to meet diverse needs. Here are some defining characteristics of elastic materials:

-

High Elasticity: Elastic materials can stretch up to several times their original length without breaking, providing exceptional flexibility.

-

Recovery: After being stretched, these materials can recover their original shape, ensuring they maintain their form and functionality over time.

-

Durability: Elastic materials are designed to withstand wear and tear, making them ideal for high-stress applications where longevity is crucial.

-

Comfort: Often used in clothing and textiles, elastic materials offer a comfortable fit and allow for ease of movement, enhancing the wearer’s experience.

These properties make elastic materials a popular choice in the textile industry, where flexibility, durability, and comfort are paramount.

Types of Stretch Materials

Stretch fabrics can be very different from each other based on their composition and purpose. Here’s a breakdown of the most common types:

Stretch fabrics can also be made from natural materials like wool and cotton, which offer unique benefits such as breathability and strength.

Spandex (Lycra®)

Spandex also known as Lycra® is an elastomeric fiber known for its high elasticity. Blended with materials like cotton, polyester or nylon, spandex provides garments with better stretch and recovery properties making it suitable for activewear, lingerie and figure hugging garments.

Spandex blends are often used to create figure flattering material that enhances the fit and aesthetics of garments.

Elastane

Similar to spandex, elastane is a synthetic fiber known for its stretch properties. It is used in garments that require a tight fit like sportswear, swimwear and leggings. Elastane can stretch up to 5 times its original length and come back to its original shape without losing its form.

New Stretch Fibers

Recent advancements have introduced new alternatives to traditional stretch materials like bi-component fibers and engineered knits. These fabrics have targeted stretch zones and better breathability for high performance requirements in fashion, sportswear and home textiles.

Blended Fabrics: Including Cotton Spandex

Combining natural fibers like cotton or wool with elastic fibers like spandex creates stretch materials. These blends have the best of both worlds, comfort and breathability with elasticity and durability.

Blended fabrics also benefit from enhanced wear resistance, making them durable and long-lasting. Cotton spandex blends are ideal for everyday garments due to their comfort and durability.

Benefits of Stretch Materials and Their Stretch Properties

Using stretch materials in your manufacturing process has several benefits for businesses and end users, encompassing all the positive properties of both the base and stretch fibers:

-

Better Comfort: Stretch fabrics follow the body, provides unmatched comfort and mobility.

-

Better Fit: Clothes made from stretch materials hugs the body, reduces fabric bunching and gives a better fit.

-

Durability: These fabrics can withstand wear and tear, perfect for garments and textiles that are used frequently.

-

Design Flexibility: Stretch materials allow for modern and ergonomic designs that caters to customer’s fashion and function preferences.

-

Versatile Applications: From clothing to home textiles, stretch fabrics is used in every market segment.

Uses and Applications of Stretch Fabrics

Stretch fabrics have revolutionized various industries with their versatility and functionality. Here are some common uses and applications:

-

Clothing: Stretch fabrics are a staple in the fashion industry, used extensively in activewear, sportswear, and everyday wear. Their ability to conform to the body provides both comfort and a flattering fit.

-

Textiles: In the textile sector, stretch fabrics like cotton spandex, cotton jersey, and polyester thread are widely used. These materials combine the breathability of natural fibers with the elasticity of synthetic ones.

-

Industrial Products: Stretch fabrics are also employed in industrial applications, including elastic fibers, neoprene rubber, and materials with advanced stretch capabilities. These products benefit from the durability and flexibility of stretch fabrics.

-

Medical Applications: In the medical field, stretch fabrics are used in wound dressings, compression bandages, and even surgical implants. Their ability to conform to the body and provide gentle compression makes them ideal for these applications.

The diverse applications of stretch fabrics underscore their importance across various sectors, from fashion to healthcare.

Stretch Material Trends

The demand for stretch materials has increased, driven by customer preferences and industry developments. Here are the trends:

Athleisure: Emphasizing Moisture Wicking

Athleisure—the combination of activewear and casual fashion—is still the trend in the apparel industry. Stretch fabrics is at the heart of this trend, provides the flexibility and comfort customers want in dual purpose clothing.

Smart Textiles

The integration of wearable technology with stretch materials is opening up possibilities in healthcare, fitness and even military applications. Stretchable fabrics now have sensors that can track movement, monitor vital signs or provide feedback during workout.

Home Textile Transformations

Stretch materials is getting popular in the home textile industry. Fitted sheets, elasticized sofa covers and multipurpose upholstery fabrics are just a few examples where stretch fabrics makes practicality and aesthetics better.

Problems and Solutions

Problem 1: Sewing and Handling

Stretch fabrics can be a problem during production like difficulty in sewing without puckering.

Solution: Use specialized sewing machine and lightweight stabilizers to handle stretch textiles.

Problem 2: Fabric Deformation

Improper handling can cause stretch material to lose its shape.

Solution: Implement strict quality control and educate your production team on how to handle stretch fabrics.

Problem 3: Cost

Specialized fibers like spandex can add to the cost.

Solution: Balance quality with cost by sourcing stretch materials from suppliers who offers competitive pricing.

Working with Stretch Fabrics

Handling and sewing stretch fabrics can be challenging, but with the right techniques and tools, it can be done effectively. Here are some tips for working with stretch fabrics:

-

Use a Stretch Needle: A stretch needle is specifically designed for sewing stretch fabrics, helping to prevent skipped stitches and broken threads.

-

Use a Walking Foot: A walking foot can guide the fabric smoothly through the sewing machine, preventing bunching or dragging.

-

Use a Stretch Stitch: A stretch stitch is tailored for sewing stretch fabrics, providing a strong and flexible seam that can withstand the fabric’s movement.

-

Use a Serger: A serger can finish seams neatly and prevent fraying, ensuring the longevity of the garment.

By employing these techniques, you can achieve professional results when working with stretch fabrics.

Sourcing and Quality Control

When sourcing stretch fabrics, consider:

-

Supplier Reputation: Partner with suppliers who has good quality and ethical practices.

-

Material Properties: Make sure the fabrics meet your specific stretch and durability requirements.

-

Manufacturing Standards: Verify if suppliers comply with industry regulations and quality certifications.

Do regular quality check to ensure your final products meet customer expectations.

Stretch Fabric Manufacturers and Suppliers

Stretch fabric manufacturers and suppliers play a pivotal role in delivering high-quality materials to a wide array of industries, including fashion, sportswear, and home textiles. These industry leaders ensure that the fabrics meet the diverse needs of their clients, from moisture-wicking capabilities to superior stretch properties.

Sustainable Stretch Materials

Sustainability is a growing concern in textile industry. While traditional elastomeric fibers are synthetic, there are eco-friendly alternatives emerging:

-

Bio-based Elastane: Made from renewable resources, bio-based elastane reduces dependence on fossil fuels.

-

Recycled Spandex: Made from pre- and post-consumer waste, recycled spandex is an eco-friendly option.

-

Plant-Based Options: Innovations using natural rubber and other plant-based materials offers biodegradable stretch fabrics.

Practicing sustainability like reducing waste and circular production can further align your business to ecological goals.

Choosing the Right Stretch Fabric

Selecting the appropriate stretch fabric depends on the specific application and desired properties. Here are some factors to consider:

-

Stretch Properties: Determine the level of stretch required for your application. Some stretch fabrics offer more stretch than others, which can impact the fit and functionality of the final product.

-

Comfort: Consider the comfort level needed for the application. Some stretch fabrics are softer and more comfortable against the skin, making them ideal for everyday wear.

-

Durability: Assess the durability required for the application. Some stretch fabrics are more resistant to wear and tear, making them suitable for high-stress environments.

-

Moisture Wicking: Evaluate the moisture-wicking properties needed for the application. Some stretch fabrics are designed to wick moisture away from the body, keeping the wearer dry and comfortable.

By considering these factors, you can choose the right stretch fabric that meets your specific needs and enhances the performance of your products.

Care and Maintenance of Stretch Fabrics

Proper care and maintenance are essential to ensure that stretch fabrics retain their stretch properties and last longer. Here are some tips for caring for stretch fabrics:

-

Wash in Cold Water: Washing stretch fabrics in cold water helps prevent shrinkage and maintains their stretch properties.

-

Avoid Using Fabric Softener: Fabric softener can reduce the elasticity of stretch fabrics, so it’s best to avoid using it.

-

Avoid Using Bleach: Bleach can damage stretch fabrics and compromise their stretch properties.

-

Dry Flat: Drying stretch fabrics flat helps prevent shrinkage and maintains their original shape.

By following these care guidelines, you can extend the life of your stretch fabrics and ensure they continue to perform well.

I hope this helps! Let me know if you need any further assistance.

Real-World Examples

Case Study 1: Activewear Success

A garment manufacturer added spandex-based stretch fabrics to their activewear line. This simple change increased customer satisfaction due to better comfort and flexibility and resulted to 30% sales growth.

Case Study 2: Home Textile Breakthrough

A home textile company used blended stretch materials for their bedding line. Their fitted sheets was durable and premium feel, gave them an edge and increased repeat purchase by 25%.

Case Study 3: Sustainable Fashion Game-Changer

A fashion brand used recycled spandex in their clothing line. This eco-friendly move appealed to their eco-conscious customers and reduced their carbon footprint by 40%.

The Future of Stretch Materials in Textiles

The textile industry will only get more dependent on stretch materials as customer demand for flexibility, durability and sustainability grows. Technology and materials innovation plus eco-friendly practices will shape the future of this industry.

Whatever you are a garment manufacturer, textile trader or home textile producer, use stretch materials wisely and be ahead of the competition.

Get in Touch

Ready to see how stretch materials can improve your products? Talk to us to know more about stretch fabrics, sourcing and textile technology.

Conclusion

Stretch fabric is a versatile and indispensable material across numerous industries, including fashion, sportswear, and home textiles. Its unique properties, such as stretch, recovery, and moisture-wicking capabilities, make it an ideal choice for creating comfortable and functional garments. As the demand for sustainable and eco-friendly materials rises, stretch fabric manufacturers and suppliers are pioneering new technologies and materials that blend stretch properties with environmental responsibility.

Understanding the different types of stretch fabrics, their properties, and applications is crucial for designers, manufacturers, and consumers. This knowledge enables informed decisions when selecting stretch fabrics, ensuring the final products meet the desired standards of comfort, durability, and sustainability.

In conclusion, stretch fabric is a remarkable material that offers a multitude of benefits, from enhanced comfort and flexibility to sustainability and eco-friendliness. As technology continues to advance, we can anticipate even more innovative stretch fabrics that cater to the diverse demands of various industries and consumers.