Mastering Bookbinding with Sewing Wire

In the intricate world of bookbinding and print finishing, the choice of materials can make all the difference. One such essential material that has been making waves in the industry is the 25-gauge round stitching wire. This post will guide you through its significance, evolution, and practical applications, helping you understand why it stands out as a preferred choice for bookbinders, print shops, and stationery enthusiasts.

Introduction to 25-Gauge Round Stitching Wire

The 25-gauge round stitching wire is a specific type of binding wire used extensively in bookbinding and print finishing. Its particular thickness and round shape make it ideal for creating durable and aesthetically pleasing bindings. This type of wire is known for its strength and flexibility, allowing for both tight and neat stitches.

Compared to traditional sewing thread, particularly waxed thread, the 25-gauge round stitching wire offers several advantages. While sewing thread is versatile and durable, especially for hand sewing projects involving materials like leather and canvas, the stitching wire provides increased stiffness and superior strength. This ensures that books and other printed materials remain intact, even with frequent use, making it a more reliable option for professional bookbinders and print shops.

Whether you are a professional bookbinder, run a print shop, or are an enthusiast looking to create beautiful stationery, the 25-gauge round stitching wire offers several benefits. Its robust nature ensures that books and other printed materials remain intact, even with frequent use.

In this blog post, we will explore the historical development of stitching wire, its advantages, practical applications, and future trends in the industry. By the end, you will have a comprehensive understanding of why 25-gauge round stitching wire is a superior choice for your binding needs.

Understanding Bookbinding Basics

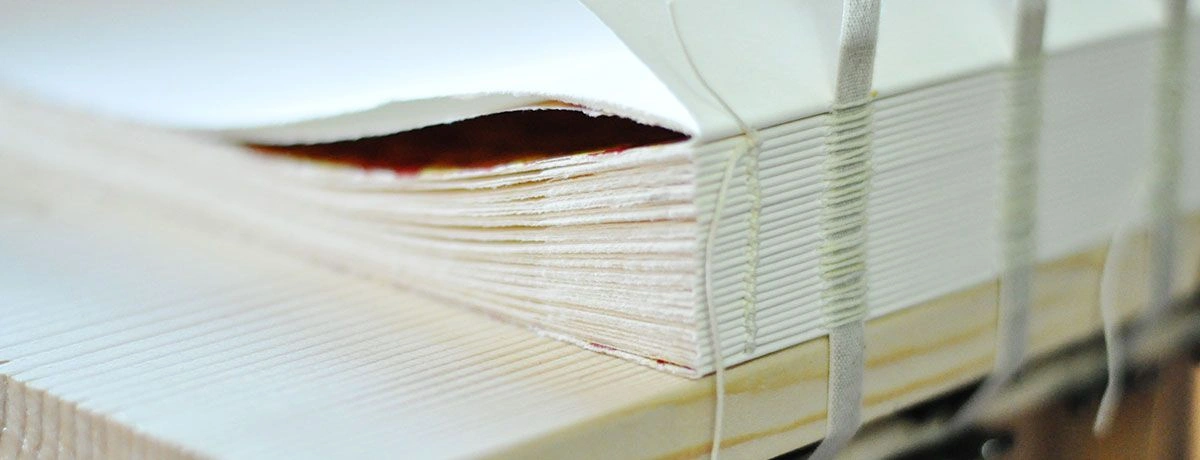

Bookbinding is the art of attaching pages together along one side and enclosing them in a cover, creating a cohesive and durable book. To master this craft, it’s essential to understand the key materials and techniques involved:

-

Sewing: At the heart of bookbinding is sewing, which involves stitching the pages together using a strong thread. Opt for top quality thread, such as waxed thread or serger thread, to ensure durability and longevity.

-

Stitches: Various stitches are used in bookbinding, each serving a different purpose. The flat stitch is ideal for creating a smooth spine, while the longstitch and chain stitch offer decorative and functional benefits.

-

Needles: Bookbinding needles are typically blunt-tipped to prevent damage to the paper. They also have a large eye to accommodate thicker threads like waxed thread or serger thread.

-

Thread: The thread used in bookbinding must be strong and durable. Waxed thread is a popular choice due to its strength and resistance to fraying. Serger thread is another excellent option for its durability.

-

Leather: Leather is often used for book covers, adding a touch of elegance and durability. When sewing leather, a waxed cord or thread is recommended to ensure a secure and lasting stitch.

By understanding these basics, you’ll be well-equipped to start your bookbinding journey, creating beautiful and durable books.

The Evolution of Stitching and Wire

The history of stitching wire is as rich and varied as the books it binds. Early bookbinding techniques relied heavily on thread and animal sinew. These materials, while effective, had limitations in terms of durability and ease of use.

The advent of metal wires marked a significant milestone in the evolution of binding materials. Initially, thicker wires were used, which provided strength but could be cumbersome to work with. Over time, advancements in metallurgy and manufacturing led to the development of thinner, more flexible wires, such as the 25-gauge round stitching wire.

This evolution has been driven by the need for more efficient and reliable binding methods. The development of 25-gauge round stitching wire represents the culmination of centuries of innovation, providing a material that combines the best attributes of its predecessors with modern advancements in technology.

The Advantages of 25-Gauge Round Stitching Wire Over Other Binding Materials

When it comes to choosing binding materials, the 25-gauge round stitching wire offers several key advantages. Compared to machine sewing, hand sewing with 25-gauge round stitching wire provides added control and precision, making it ideal for detailed work on leather and canvas. Additionally, using waxed thread for hand sewing enhances durability and water resistance, which is particularly beneficial for crafting wallets, belts, and other leather goods.

Durability

Durability is one of the most significant benefits of 25-gauge round stitching wire. Its robust construction ensures that it can withstand the rigors of frequent handling and use. Unlike thread or thinner wires, it does not fray or break easily, making it ideal for binding books that will see heavy use.

Flexibility

Flexibility is another crucial advantage. The 25-gauge thickness strikes a perfect balance between being sturdy and easy to manipulate. This flexibility allows for tighter and more precise stitches, resulting in a cleaner and more professional finish.

Aesthetics

Aesthetics also play a vital role in the appeal of 25-gauge round stitching wire. Its round shape and consistent thickness provide a uniform appearance, enhancing the overall look of the bound material. Whether used in books, journals, or other printed materials, it contributes to a polished and high-quality finish.

Practical Applications and Best Practices for Using 25-Gauge Round Stitching Wire

The practical applications of 25-gauge round stitching wire are vast and varied. It can be used for crafting items like belts, in addition to books and other printed materials. Here are some best practices for maximizing its potential:

Print Shops

For print shops, 25-gauge round stitching wire is invaluable for producing high-quality bound materials. Whether you are binding catalogs, brochures, or best-selling novels, this wire ensures a professional and durable finish. It's essential to maintain proper tension and alignment during the binding process to achieve the best results.

Bookbinders

Professional bookbinders will find the 25-gauge round stitching wire indispensable for both new bindings and restoration projects. Its strength and flexibility make it suitable for various binding styles, from case binding to saddle stitching. Ensuring that the wire is tightly wound and properly secured will result in a long-lasting and attractive binding.

Stationery Enthusiasts and Needle Use

Stationery enthusiasts can use 25-gauge round stitching wire to create unique and personalized journals, notebooks, and planners. Its ease of use allows for creative designs and intricate patterns. Experimenting with different stitch styles and patterns can result in one-of-a-kind creations.

Tips for Sewing with Wire

Sewing with wire can be a unique and rewarding experience, but it does come with its challenges. Here are some tips to help you navigate the process with ease:

-

Use the Right Needle: A blunt-tipped needle is ideal for sewing with wire. It prevents the wire from being pierced and breaking, ensuring a smoother sewing process.

-

Choose the Right Thread: When sewing with wire, it’s crucial to use a strong thread. Top quality thread, such as waxed thread, provides the necessary strength and durability.

-

Use a Thimble: Protect your fingers from the wire by using a thimble. This small tool can prevent injury and make the sewing process more comfortable.

-

Keep the Wire Taut: To avoid tangling or kinking, keep the wire taut as you sew. This will help maintain a clean and precise stitch.

-

Use a Wire Pull: A wire pull can be incredibly helpful when sewing with wire. It assists in pulling the wire through fabric or leather, making the process easier and more efficient.

By following these tips, you’ll find sewing with wire to be a more manageable and enjoyable task, resulting in professional and durable bindings.

Bookbinding Tools and Materials

To achieve the best results in bookbinding, it’s essential to use the right tools and materials. Here are some of the most common ones:

-

Bookbinding Needles: Blunt-tipped needles with a large eye are perfect for bookbinding. They prevent damage to the paper and accommodate thicker threads.

-

Waxed Thread: This strong and durable thread is ideal for sewing pages together. Its wax coating prevents fraying and ensures a secure stitch.

-

Serger Thread: Known for its strength and durability, serger thread is another excellent choice for bookbinding.

-

Leather: Often used for book covers, leather adds a touch of elegance and durability. It can be sewn using a waxed cord or thread for a secure and lasting finish.

-

Wire: Used for sewing and shaping book covers, wire can be coated with varnish to prevent electrical shorts and ensure a clean finish.

-

Bookbinding Glue: A strong adhesive is essential for attaching pages together and securing the cover to the book.

-

Bookboard: This stiff, thick paperboard is used to create the cover of a book, providing structure and durability.

By using these top-quality tools and materials, you’ll be well-equipped to create beautiful and durable books.

Case Studies

The Binding of Bestsellers

XYZ Print Shop successfully utilized 25-gauge round stitching wire to bind a series of best-selling novels. The durability and aesthetic appeal of the wire contributed to high customer satisfaction, with readers appreciating the quality and longevity of their books.

Reviving History

A bookbinder specializing in the restoration of antique books used 25-gauge round stitching wire to restore a collection of rare books. The wire's flexibility and strength were crucial in preserving the integrity of these historical works, ensuring they could be enjoyed by future generations.

Innovative Design Meets Functionality

ABC Creations, a stationery company, incorporated 25-gauge round stitching wire into their product line of journals and notebooks. The wire's aesthetic appeal and durability enhanced the overall quality of their products, making them a favorite among customers.

Troubleshooting Bookbinding Issues

Even with the best tools and materials, issues can arise during the bookbinding process. Here are some common problems and how to troubleshoot them:

-

Thread Breakage: If your thread breaks while sewing, consider using a stronger thread like waxed thread or serger thread. Adjusting the tension of the thread can also help prevent breakage.

-

Wire Tangling: To avoid wire tangling or kinking, use a wire pull and keep the wire taut as you sew. This will help maintain a clean and precise stitch.

-

Leather Cracking: If the leather cracks while sewing, try using a leather conditioner to soften it. Adjusting the tension of the thread can also help prevent cracking.

-

Pages Not Aligning: If your pages do not align properly, use a ruler or other straightedge to guide your needle. This will help ensure a straight and even stitch.

-

Cover Not Attaching Properly: If the cover does not attach properly to the book, try using a stronger adhesive. Adjusting the position of the cover can also help achieve a better fit.

By addressing these common issues, you’ll be able to troubleshoot and resolve problems quickly, ensuring a smooth and successful bookbinding process.

Future Trends in Bookbinding

The future of bookbinding is poised for exciting advancements, with 25-gauge round stitching wire playing a significant role. Emerging trends include the integration of sustainable materials and the use of smart technologies to enhance the binding process.

Sustainable Materials

Sustainability is becoming increasingly important in the printing and bookbinding industry. The use of eco-friendly materials, including stitching wires made from recycled metals, is expected to grow. This shift towards sustainability aligns with broader environmental goals and meets the growing demand for green products.

Smart Technologies

Advancements in smart technologies are also set to revolutionize the bookbinding process. Automated binding machines equipped with AI and machine learning capabilities can optimize the use of 25-gauge round stitching wire, ensuring precision and efficiency. This technological integration will enhance productivity and consistency in binding quality.

Customization

Customization is another trend gaining momentum. With the help of advanced binding technologies, businesses can offer personalized binding options to their customers. This includes custom stitch patterns, wire colors, and binding styles, allowing for unique and tailored products.

Conclusion

Choosing the right binding material is crucial for ensuring the quality and longevity of your printed materials. The 25-gauge round stitching wire stands out as an exceptional choice due to its durability, flexibility, and aesthetic appeal. Whether you are a bookbinder, print shop owner, or stationery enthusiast, this wire offers numerous benefits that enhance the quality of your work.

By understanding the historical evolution, practical applications, and future trends related to 25-gauge round stitching wire, you can make informed decisions that elevate your binding projects. Consider incorporating this versatile material into your binding process and experience the difference it can make.

If you are ready to take your bookbinding to the next level, explore our range of 25-gauge round stitching wire and discover how it can transform your projects. Visit our website to learn more and get started with the best in binding materials today.