A Guide to Understanding Embroidery Thread Weight for Your Projects

Choosing the right thread weight is key to successful embroidery. Whether you're a pro or a beginner, understanding thread weight helps you achieve the desired look, feel, and durability. This guide covers embroidery thread weight, its impact on your work, and which type suits your projects.

As a thread factory worker, MH will help you understand thread weight, size conversions, and how to choose the right thread for your needs.

What is Thread Weight?

Thread weight refers to the thickness or fineness of a thread. It’s typically represented by a number, where lower numbers indicate thicker threads, and higher numbers correspond to finer threads. For example, a 30-weight thread is thicker than a 50-weight thread.

Why is thread weight important? It significantly influences how your stitch looks, the fabric’s appearance, and even the functionality of the finished project. When working on embroidery, quilting, or general sewing projects, selecting the appropriate thread weight ensures a professional finish and minimizes potential issues like thread breakage or tension problems. Understanding the significance of different thread weights can enhance the overall enjoyment and outcome of your sewing, quilting, or embroidery projects.

Types of Embroidery Threads

There are several types of embroidery threads available, each catering to specific needs and fabrics. Let’s explore some of the most common types. These threads come in both solid and variegated colors, offering a diverse range of palettes to enhance the visual appeal and creativity of your embroidery projects.

1. Polyester Embroidery Threads

Polyester threads are durable, colorfast, and resistant to fading, making them an excellent choice for machine embroidery. They are known for their strength and ability to withstand high-speed sewing machine operations without breaking. Popular for vibrant, high-sheen designs, polyester thread is versatile and widely used across various projects.

2. Rayon Embroidery Threads

Rayon threads offer a luxurious feel and glossy finish, often chosen for decorative embroidery. However, they are less durable than polyester and may not be suitable for projects requiring frequent washing or exposure to external elements.

3. Cotton Embroidery Threads

Cotton thread, known for its soft texture and matte finish, is ideal for classical and traditional embroidery styles. They come in various weights and are favored for heirloom projects and hand embroidery.

4. Perle Cotton Threads

Perle cotton threads are thicker and non-divisible, offering a bold appearance for hand embroidery and specific decorative sewing techniques. They come in different weights, with smaller numbers signifying thicker threads.

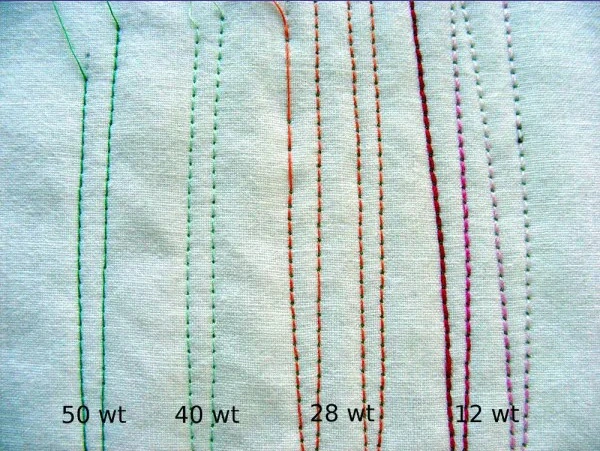

Thread Weight Comparison

Understanding how thread weights differ is crucial for selecting the right one for your project. Below is a breakdown of thread weights and their common applications:

Thread weight, often denoted as 'wt thread,' is a measurement of length versus weight.

Medium Weight Threads (40-50wt)

-

Uses: Machine embroidery, sergers, quilting, and general-purpose sewing.

-

Ideal for designs with moderate detail and coverage.

Fine Weight Threads (60-100wt)

-

Uses: Intricate embroidery, micro-quilting, appliqué, and detailed stitch work.

-

Great for delicate projects requiring fine lines and precision. A finer thread allows for intricate details, making it ideal for high-thread-count fabrics and precise detailing.

Heavy Weight Threads (12-30wt)

-

Uses: Bold machine quilting, decorative stitching, thread painting, crafts, and hand embroidery.

-

Produces textured, dramatic stitches that stand out visibly on fabric. Thicker thread creates bolder, more textured stitches, making it ideal for prominent designs and enhancing textural contrasts in various projects.

Thread Conversion Basics

To better understand thread measurements:

-

Weight to Denier = 9000/weight

-

Weight to Tex = 1000/weight

-

For example, a 40-weight thread equals 225 denier and Tex 25.

Choosing the Right Thread Weight for Your Project

Each project has unique requirements, and selecting the right thread weight is key to achieving optimal results. Consider the following factors to make an informed choice:

1. Type of Embroidery

-

For machine embroidery, use medium weights (40-50wt) for versatile, general-purpose designs, or fine weights (60-100wt) for intricate designs requiring precision.

-

For hand embroidery, heavier threads (12-30wt) create bold designs, while finer threads achieve delicate details.

2. Fabric

The fabric you’re working with greatly impacts the thread weight choice. Thicker fabrics often require heavier threads for better visibility and durability, whereas delicate fabrics pair best with fine threads to prevent damage.

3. Stitch Density

Denser embroidery designs benefit from finer threads to avoid overcrowding the fabric surface. Conversely, sparse or open designs may look better with thicker threads that add visual interest and texture.

4. Needle Size

Pair thread weight with the correct sewing machine needle size. Heavier threads require larger needles to accommodate their thickness, while finer threads work with smaller needles to maintain precision.

5. Tension Settings

Adjust the tension settings on most sewing machines according to thread weight. Thicker threads typically need more tension, while finer threads operate with less tension for smooth results.

Thread Weight in Specific Applications

Thread weight plays a crucial role in the outcome of different sewing techniques. Here’s a quick look at thread recommendations for various uses:

Machine Embroidery

-

40-50wt threads are industry standards for machine embroidery.

-

60wt or finer threads add a polished finish to highly detailed tasks or tiny lettering.

Hand Embroidery

-

Use 30wt or heavier threads for bold textures, such as in big-stitch embroidery or sashiko.

-

Opt for 60wt or lighter threads to create fine, detailed hand-stitching.

Quilting

-

Choose 40-50wt threads for piecing and machine quilting.

-

For bold stitches, such as in visible quilting designs, use 12-30wt threads.

Thread Weight and Project Outcomes

Using the correct thread weight not only enhances the visual appeal of your project but also improves its overall quality and longevity. Here’s what to keep in mind:

-

Durability: Heavier threads add strength and durability, ideal for frequently used or washed items.

-

Stitch Definition: Fine threads create clean and precise stitches, while thicker threads provide bold and dramatic effects.

-

Professional Finish: Correct thread weight ensures smooth stitching, reduced thread breakage, and optimal tension.

Additionally, adjusting the stitch length is crucial for achieving optimal design coverage and aesthetics, especially when using thicker threads. Increasing the stitch length can help prevent issues like a lumpy look or thread jams.

Achieving Professional Results with the Right Thread Weight

To take your embroidery work to the next level, remember these tips:

-

Test thread weights on scrap fabric before committing to your final project.

-

Match your bobbin thread to your top thread weight to avoid tension issues.

-

Experiment with thread types and weights to discover what works best for your unique style.

Investing time in understanding thread weight will undoubtedly elevate your embroidery creations, giving them a polished and professional finish.