How Do Embroidery Backings Optimize Production Efficiency?

In commercial garment manufacturing, embroidery quality directly influences the perceived value of the final product. A perfect design on a screen can result in puckering, distortion, or misalignment if the underlying support is insufficient. The critical variable in this equation is the embroidery backing (or stabilizer).

For procurement managers, wholesalers, and factory operators, understanding the technical specifications of embroidery backings is essential for reducing defect rates and optimizing production efficiency. This guide outlines the categories, applications, and selection criteria for embroidery backings, tailored for B2B buyers sourcing materials for large-scale manufacturing.

MH serves as a direct supplier and manufacturer for these essential components, offering make-to-order solutions that meet specific industrial requirements.

Defining Embroidery Backings and Stabilizers

In industrial textiles, embroidery backing is the material placed beneath the fabric being embroidered. Its primary purpose is to provide stability during the needle penetration process, preventing the fabric from shifting, stretching, or puckering under the tension of high-speed embroidery machines.

While the terms are often used interchangeably, a distinction exists in application. "Backing" generally refers to the material that stays behind the embroidery (either permanently or temporarily) to support the stitches. "Stabilizer" can sometimes refer to toppings placed over the fabric (such as water-soluble film on towels) to prevent stitches from sinking into the pile.

This guide targets professional buyers and production managers seeking to match the correct backing specifications to their garment orders.

Types of Embroidery Backing

Backings are categorized primarily by how they are removed from the finished product and their weight. MH classifies these materials to help manufacturers balance stability with efficiency.

Weight and Stability

Backings typically come in lightweight, medium-weight, and heavyweight options. The general rule in manufacturing is that the heavier the stitch count (density), the heavier the backing required to support it. Using a backing that is too light for a dense design will result in registration errors (misalignment), while a backing that is too heavy can ruin the drape of the garment.

Cut-Away Backing

Cut-away backing is a permanent stabilizer designed to remain on the garment throughout its lifecycle. It provides the highest level of stability.

-

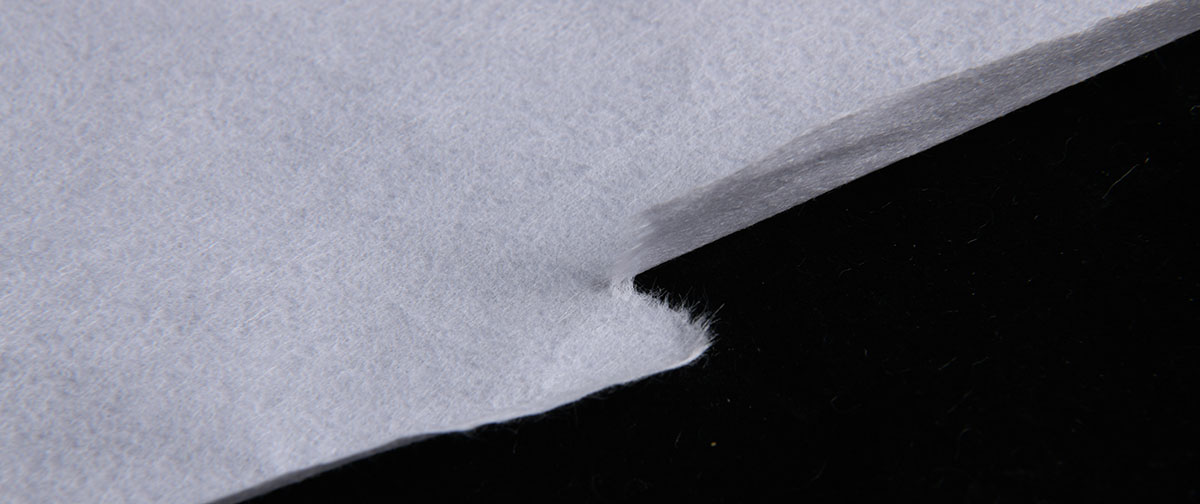

Material Composition: Non-woven fibers bound together to resist stretching in all directions.

-

Best Suited Fabrics: Unstable, stretchy fabrics such as knits, fleece, and spandex. It prevents the design from distorting when the garment stretches during wear or washing. Learn more about essential tailoring materials.

-

Trimming: In a production setting, operators trim the excess backing away from the design edges after embroidery. A margin of approximately 2-3mm is typically left to ensure the stitches remain secure.

Tear-Away Backing

Tear-away backing is a temporary stabilizer designed for speed and efficiency. It is engineered to tear easily in all directions, facilitating rapid removal.

-

Material Composition: Non-woven material with shorter fibers that separate cleanly under tension.

-

Best Suited Fabrics: Stable woven fabrics like denim, canvas, and heavy cotton twill that do not stretch significantly. It is also standard for items where the back of the embroidery is visible, such as towels or scarves.

-

Removal: Operators tear the backing away after stitching. It is crucial to support the stitches during removal to prevent thread distortion.

Water-Soluble Backing

Water-soluble backing (or topping) dissolves completely when exposed to water, leaving no residue.

-

Properties: Created from polyvinyl alcohol (PVA) or similar compounds. It can serve as a backing for lace-making (where no fabric remains) or a topping for textured fabrics.

-

Ideal Applications: High-pile fabrics like terry cloth, velvet, or fleece (to keep stitches elevated), and freestanding lace.

-

Dissolution: In industrial finishing, the garments undergo a wash cycle or steam treatment to dissolve the stabilizer.

Fusible and Heat-Soluble Options

-

Fusible Backing: One side is coated with a heat-activated adhesive. It is ironed onto the fabric before hooping to prevent shifting. This is ideal for slippery performance fabrics.

-

Heat-Soluble Film: Similar to water-soluble options but removed via a heat press or iron. This avoids the need for wet processing in the finishing stage.

How To Choose The Best Backing

Procurement managers must select backings that minimize material costs while maximizing product quality.

-

Assess Fabric Stability: If the base fabric stretches (knits), choose Cut-Away. If the fabric is stable (wovens), Tear-Away is generally sufficient and faster to process.

-

Match Stitch Density:

-

Low density (<10,000 stitches): Lightweight backing.

-

Medium density (10,000 - 25,000 stitches): Medium-weight backing.

-

High density (>25,000 stitches): Heavyweight backing or multiple layers of medium-weight.

-

-

Common Use-Cases:

-

Polo Shirts (Pique Knit): Medium-weight Cut-Away.

-

Caps/Hats: Heavyweight Tear-Away (often specifically stiffened for cap frames).

-

Dress Shirts (Woven): Medium-weight Tear-Away.

-

-

Test Samples: As MH operates on a make-to-order basis, requesting sample yardage to test on the specific production fabric is recommended before commissioning a mass order.

Backings For Sensitive Skin

For garments worn directly against the skin—such as infant wear, lingerie, or activewear—texture is a critical quality parameter. Standard cut-away backings can be scratchy and cause irritation.

MH recommends sourcing "soft-touch" or specialized fusibles for these applications. Alternatively, covering the back of a finished embroidery with a secondary layer of soft, fusible interlining (often called "comfort backing") ensures the consumer feels only a smooth surface.

Application, Hooping, and Removal

Proper technique on the factory floor is as important as the material itself.

-

Hooping: For stretch fabrics, the backing and fabric must be hooped together with neutral tension. Stretching the fabric during hooping results in puckering once the garment relaxes.

-

Ironing Fusibles: If using fusible backing, ensure the heat press temperature matches the adhesive's activation point without scorching the delicate fabric.

-

Removal Sequence: For tear-away, operators should tear the backing close to the stitching to minimize cleaning time, but gently enough to avoid distorting the design edges.

Testing, Washing, and Care

Quality Assurance (QA) teams should implement a wash-test protocol for any new backing/fabric combination.

-

Durability Test: Embroider a sample and subject it to three industrial wash-and-dry cycles.

-

Inspection: Check for "baconing" (curling edges), backing shrinkage, or adhesive bleed-through. If the backing shrinks more than the fabric, the design will pucker.

-

Adjustment: If defects appear, adjust the backing weight or switch types (e.g., from tear-away to cut-away) before approving the bulk production run.

Best Backing Product Checklist

When sourcing from MH, use the following attributes to specify your order requirements:

-

Weight: Measured in grams per square meter (GSM) or ounces.

-

Hand Feel: Soft vs. Crisp/Stiff.

-

Fusible Strength: Level of adhesion required.

-

Washability: Tolerance for industrial laundering or dry cleaning.

-

Skin Safety: Compliance with Oeko-Tex or relevant safety standards for babywear.

Comparison Table and Example Use-Cases

The following table aids in quick decision-making for procurement:

|

Backing Type |

Stability |

Removal Method |

Primary Use Case |

|---|---|---|---|

|

Cut-Away |

High |

Trim with scissors |

Knits, Athletic Wear, Fleece |

|

Tear-Away |

Medium |

Tear by hand |

Denim, Towels, Caps, Bags |

|

Water-Soluble |

Low (Structural) |

Dissolve in water |

Freestanding Lace, High-Pile Topping |

|

Fusible |

High (Adhesion) |

Permanent |

Slippery/Unstable Fabrics |

Real-World Production Pairings

-

Corporate Polos: Use 2.5oz Cut-Away. The knit fabric requires permanent stability to hold the logo shape over years of washing.

-

Canvas Tote Bags: Use 3.0oz Tear-Away. The canvas is stable; the backing is needed only for the hooping process and can be removed quickly for a clean finish.

-

Plush Towels: Use Water-Soluble Topping + Tear-Away Backing. The topping prevents stitches from sinking, while the backing supports the needle penetration.

Common Problems and Troubleshooting

-

Puckering: Usually caused by hooping the fabric too tightly or using a backing that is too light for the stitch density. Switch to a heavier cut-away backing.

-

Backing Separation: If fusible backing bubbles or separates, the heat press temperature was likely insufficient or the dwell time too short during application.

-

Perforation (Cookie Cutter Effect): If the needle penetrations cut a hole around the design, the backing is too light, or the stitch density is too high. Increase backing support.

FAQs

What is the Minimum Order Quantity (MOQ) for custom backing?

As MH operates on a make-to-order model, MOQs vary based on the specific material composition and width required. Contact the sales team for specific figures tailored to your production needs.

Can MH customize the width of the backing rolls?

Yes. MH supplies backing rolls slit to specific widths to fit various industrial embroidery machine frames, reducing waste and labor on the production floor.

Is backing necessary for all embroidery?

Yes. Without backing, fabric lacks the stability to support thousands of needle penetrations, leading to distorted designs and potential machine damage.

Moving Forward with MH

Selecting the right embroidery backing is a strategic decision that impacts production speed and product quality. MH provides the manufacturing capability to supply high-performance textile accessories tailored to industrial specifications.

For detailed quotes, sample requests, or to discuss custom specifications for your next production run, contact the MH team today.