The Ultimate Guide to Breathable Water Repellent Fabric for Outdoor Apparel

Introduction

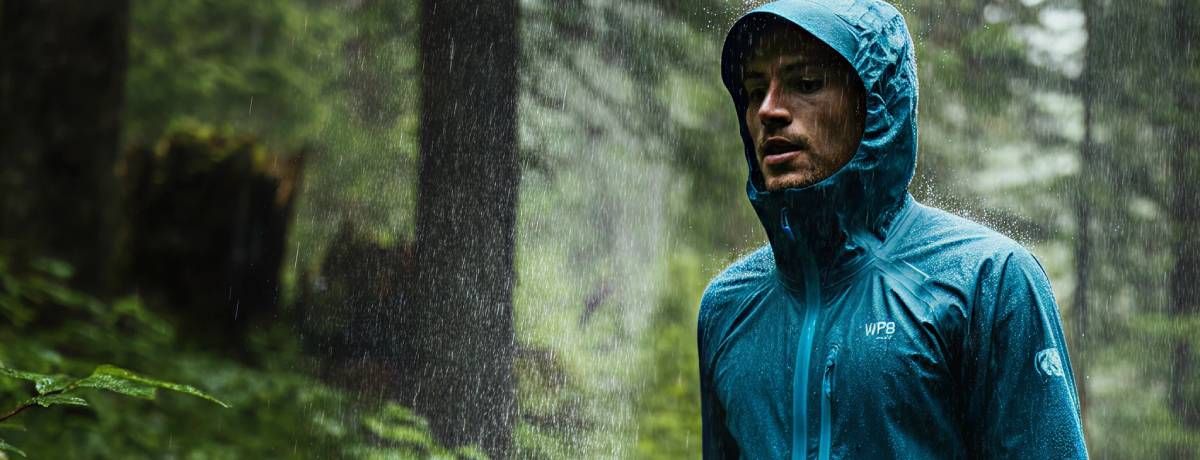

Outdoor adventures demand gear that performs under the toughest conditions. For apparel brands catering to outdoor enthusiasts and athletes, delivering products that combine weather protection with comfort is crucial. Breathable waterproof fabrics (WPB fabrics) are revolutionizing outdoor apparel by addressing the long-standing challenge of keeping users dry while preventing overheating through the use of a waterproof breathable membrane.

If your brand is designing hiking jackets, trail-running gear, or snow apparel, understanding WPB fabric technology can elevate your products and customer experience. These fabrics are designed to allow moisture vapor, such as sweat, to escape from the inside of the garment while repelling external water, maintaining breathability and comfort. This guide breaks down the essentials of WPB fabrics, their key applications, and why these innovative materials are a game-changer for outdoor performance wear.

What Are Waterproof Breathable Fabrics?

Breathable waterproof fabrics are cutting-edge materials designed to safeguard against the elements while enhancing comfort during high-intensity activities. Densely woven fabric plays a crucial role in minimizing water penetration while maintaining breathability.

These fabrics excel in their ability to:

-

Block external moisture such as rain, snow, and wind.

-

Release internal sweat vapor through the fabric layer to prevent clamminess.

-

Deliver durability and flexibility for active use.

Key Types of WPB Fabrics

-

Laminated Membranes:

-

How it Works: Microporous layers block water while allowing vapor to escape. Hydrophilic membranes provide waterproof and breathable properties by attracting and absorbing water while letting moisture vapor escape.

-

Best For: High-end mountaineering jackets (e.g., Gore-Tex, eVent).

-

DWR-Coated Fabrics:

-

How it Works: A Durable Water-Repellent finish causes water to bead up and roll off. The face fabric is crucial in maintaining water repellency by preventing water from saturating the outer layer.

-

Best For: Lightweight windbreakers, hiking pants.

-

Hybrid WPB Fabrics:

-

How it Works: Combines stretch capabilities with waterproofing.

-

Best For: Trail-running gear, climbing shells.

How do Waterproof Breathable Fabrics Work?

Waterproof breathable fabrics are marvels of modern textile engineering, designed to keep you dry and comfortable in the harshest conditions. These fabrics are a staple in outdoor clothing, from rain jackets and ski pants to hiking gear, and even find applications in industrial and military settings.

Why Outdoor Brands Need WPB Fabrics

1. Seamless Weather Protection and Breathability

Traditional waterproof fabrics often trap sweat, leaving wearers uncomfortable. WPB fabrics, on the other hand, offer superior protection from rain and snow without sacrificing breathability. The outer shell fabric plays a crucial role in providing weather protection by serving as the topmost layer in multi-layered fabric laminates. This dual functionality, achieved through the use of waterproof breathable membranes, makes them ideal for alpine climbers, ultrarunners, and backpackers facing challenging weather conditions.

2. Enhanced Comfort and Customer Satisfaction

Products made with WPB fabrics feel lightweight and flexible, creating a second-skin quality. The waterproof material contributes to comfort by allowing moisture vapor to escape while providing a barrier against external elements. This improves wearability during extended activities, translating to longer usage and higher customer satisfaction. Waterproof garments play a crucial role in customer satisfaction by maintaining their performance and protecting against various weather conditions. These benefits encourage repeat purchases, ultimately driving more sales for brands.

3. Long-Lasting Durability with Durable Water Repellent

Modern WPB fabrics are engineered to resist abrasion and retain water repellency even after 50+ washes. The role of a waterproof membrane in these fabrics is crucial for preventing water penetration while maintaining breathability, which significantly contributes to their durability. By reducing wear and tear, these fabrics minimize product returns due to “failed waterproofing,” building trust and loyalty among customers. Additionally, advancements in waterproof breathable membranes have further enhanced the longevity and performance of these products.

Applications of WPB Fabrics in Outdoor Gear

????️ 1. Hiking & Mountaineering Jackets

-

Demand: Weatherproofing with superior breathability for alpine athletes. The fabric layer in these jackets plays a crucial role in protecting against environmental elements while allowing moisture to escape, ensuring comfort during intense activities.

-

Solution: 3-layer laminated WPB fabrics with a waterproof breathable membrane for maximum protection and airflow.

???? 2. Climbing & Alpine Shells

-

Demand: Stretchable fabrics to enable dynamic movement while staying waterproof. The face fabric in these shells plays a crucial role in protecting the inner membrane and ensuring breathability, especially when treated with a Durable Water Repellent (DWR) to prevent water saturation.

-

Solution: Hybrid WPB materials with 4-way stretch capabilities. These materials incorporate advanced waterproof breathable membranes, which offer both flexibility and protection, addressing the challenges of creating garments that are both waterproof and breathable.

???? 3. Trail-Running & Fastpacking Gear

-

Demand: Ultra-lightweight weatherproof clothing for high-output activities. These fabrics are designed to allow moisture vapor, such as sweat, to escape from the inside of the garment while repelling external water.

-

Solution: DWR-coated 2.5-layer waterproof breathable fabric for lightweight performance.

⛷️ 4. Ski & Snowboard Apparel

-

Demand: Insulated, yet breathable jackets and pants for wintry conditions. The outer surface of these garments plays a crucial role in ensuring that the fabric interacts effectively with water, allowing the membranes to absorb water while permitting moisture vapor to escape.

-

Solution: Waterproof breathable membranes combined with thermal linings provide the necessary insulation while maintaining breathability, ensuring comfort and protection in wintry conditions.

Caring for Waterproof Breathable Fabrics

Proper care is essential to maintain the performance and longevity of your waterproof breathable fabrics. Here are some practical tips to help you keep your gear in top condition:

The Future of WPB Fabrics

Innovation in WPB technology is shaping the future of outdoor apparel. Brands that adopt next-generation advancements in waterproof breathable fabric stand to differentiate themselves in the marketplace by offering premium performance gear that keeps users dry and comfortable in challenging weather conditions.

Key trends to watch:

-

Eco-Friendly Coatings: PFAS-free DWR alternatives to protect the environment.

-

Self-Cleaning Membranes: Reducing maintenance for long-term use.

-

Smart Textiles: Materials that adjust breathability based on activity level, ensuring optimal comfort and efficiency.

-

Waterproof Breathable Membranes: Exploring advancements in ePTFE and microporous membranes to enhance the balance between waterproofing and breathability in outdoor clothing and gear.

How Your Brand Can Leverage WPB Fabrics

1. Test Different Options

Experiment with laminated, coated, and hybrid WPB fabrics to find the ideal material for your product line. Hydrophilic membranes, designed to attract and absorb water while allowing moisture vapor to escape, play a crucial role in these tests by ensuring the fabrics remain waterproof and breathable.

Field testing with athletes and enthusiasts can provide valuable feedback on the performance of various waterproof breathable membranes. These tests help evaluate the effectiveness of different types of membranes, including ePTFE and microporous options, in creating garments that offer both waterproof and breathable properties.

2. Educate Your Market

Highlight the unique features of WPB fabrics in your marketing—focus equally on breathability and waterproof performance. Use simple yet informative language to explain to consumers why your gear stands out. Emphasize the importance of waterproof breathable fabric in ensuring comfort and protection in challenging weather conditions.

When explaining features, mention the advancements in waterproof breathable membranes. Discuss the different types of membranes available, such as ePTFE and microporous membranes, and highlight their technical aspects, benefits, and drawbacks. This will help consumers understand the superior performance of your outdoor clothing and gear.

3. Promote Performance and Versatility

Showcase the dual functionality of WPB fabrics in your branding. Waterproof breathable fabric is versatile, providing protection and comfort in various weather conditions. Use testimonials, demo videos, or infographics that emphasize the real-world benefits for hikers, climbers, or runners.

Highlight the advancements in waterproof breathable membranes, showcasing their ability to keep users dry while allowing moisture to escape. Discuss the different types of membranes available, such as ePTFE and microporous membranes, and their benefits in outdoor clothing and gear.

Conclusion

Breathable waterproof fabrics are a must-have for outdoor apparel, offering customers the perfect balance of weather protection, breathability, and durability. Waterproof breathable fabric is essential in outdoor clothing and gear, as it keeps users dry and comfortable in challenging weather conditions. For outdoor brands, leveraging WPB fabrics is no longer an option—it’s an expectation.

By adopting the latest in WPB innovation, including advanced waterproof breathable membranes, your business can save customers the compromise between function and comfort. Are you ready to enhance your product line and stand out in the performance gear market?

Don’t wait—start exploring WPB fabrics today and build gear that your customers will trust on every adventure.