The Application and Importance of Fire Resistant Fabric

MH is committed to the development and production of high-quality FR fabrics, delivering critical fire protection solutions for industries where the safety of the workforce is paramount. Protective clothing, specifically designed for hazardous work environments such as welding and metalworking, plays a crucial role in ensuring safety and protection. MH’s FR fabrics are engineered for reliability, comfort, and compliance with international standards, making them indispensable in sectors such as emergency response, oil and gas, metallurgy, and electrical safety. This article details the primary applications and real-world advantages of MH FR fabrics, supported by globally recognized certifications.

Introduction to Fire Resistant Fabric

Flame retardant fabric is a specialized material designed to resist ignition and slow the spread of fire, providing crucial protection in high-risk environments. These fabrics are engineered to withstand exposure to flames and high temperatures, making them essential in industrial and military applications, as well as in public spaces like theaters and auditoriums. FR fabrics can be crafted from a variety of materials, including natural fibers such as cotton and synthetic fibers like polyester. Some fabrics are inherently flame retardant, meaning the fibers themselves possess fire-resistant properties, while others are treated with chemicals to enhance their ability to resist fire. This versatility allows flame retardant fabrics to be tailored to specific needs, ensuring optimal protection and performance in diverse settings.

Types of Flame Retardant Materials

FR fabrics come in various types, each offering unique advantages and applications. Inherently FR fabrics are made from fibers that are naturally flame-resistant, such as aramid, modacrylic, and polyester. These fabrics retain consistent flame-resistant properties throughout their entire lifespan without the need for additional treatments. Chemically treated fabrics, on the other hand, are made from fibers that are not naturally flame-resistant, such as cotton and polyester, and are enhanced through special chemical treatments to improve their flame resistance. This treatment can be applied to a wide range of fabrics, making them suitable for different scenarios, including industrial protective clothing and flame-resistant accessories.

Additionally, natural fibers like cotton and wool can also achieve flame resistance through chemical treatments, but their effectiveness often depends on the specific treatment techniques and standards used.

Each type of flame-resistant material has its own unique benefits, offering tailored solutions based on specific safety needs. For more information about detailed materials, please visit: https://www.mh-chine.com/scenarios/workwear-accessories/fr-materials

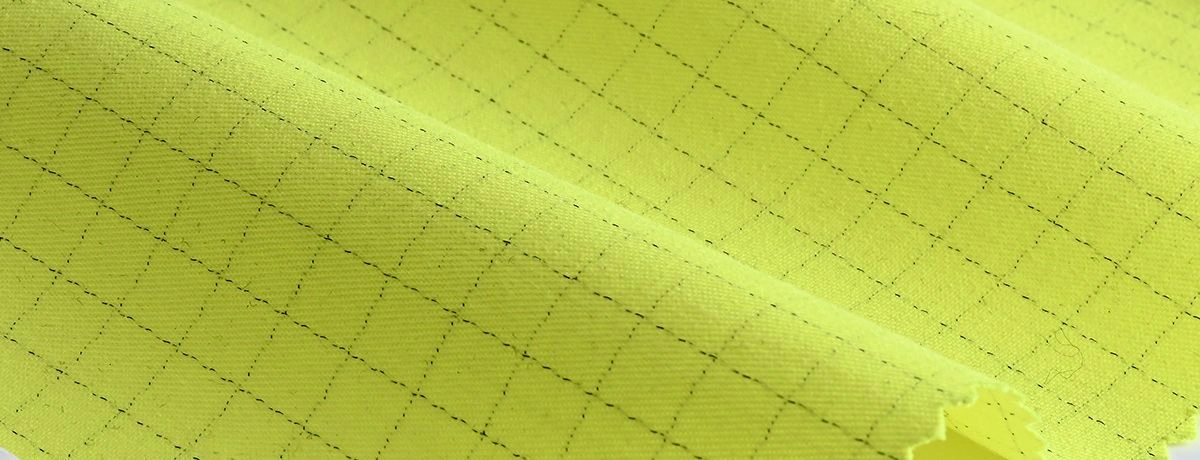

60% Modacrylic 40% Cotton FR Interlock

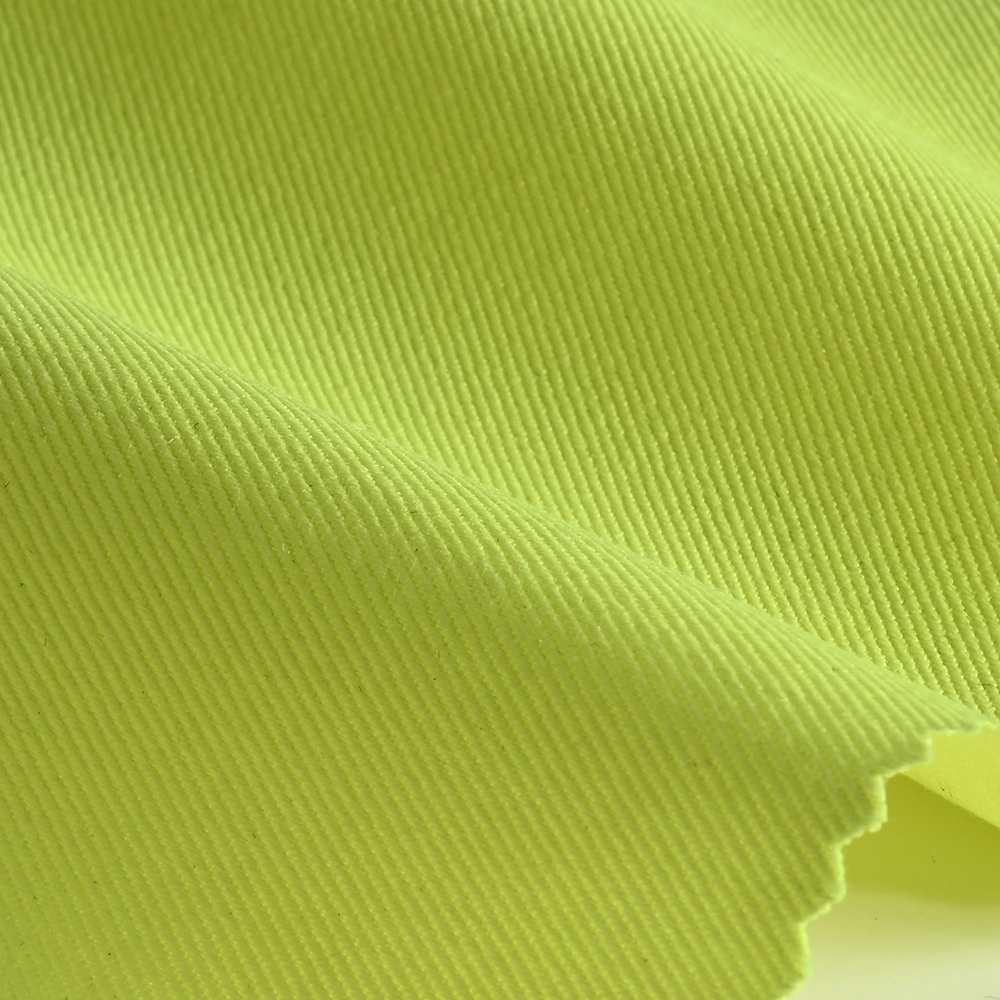

88% Cotton 12% Nylon FR Twill

100% Cotton FR Denim

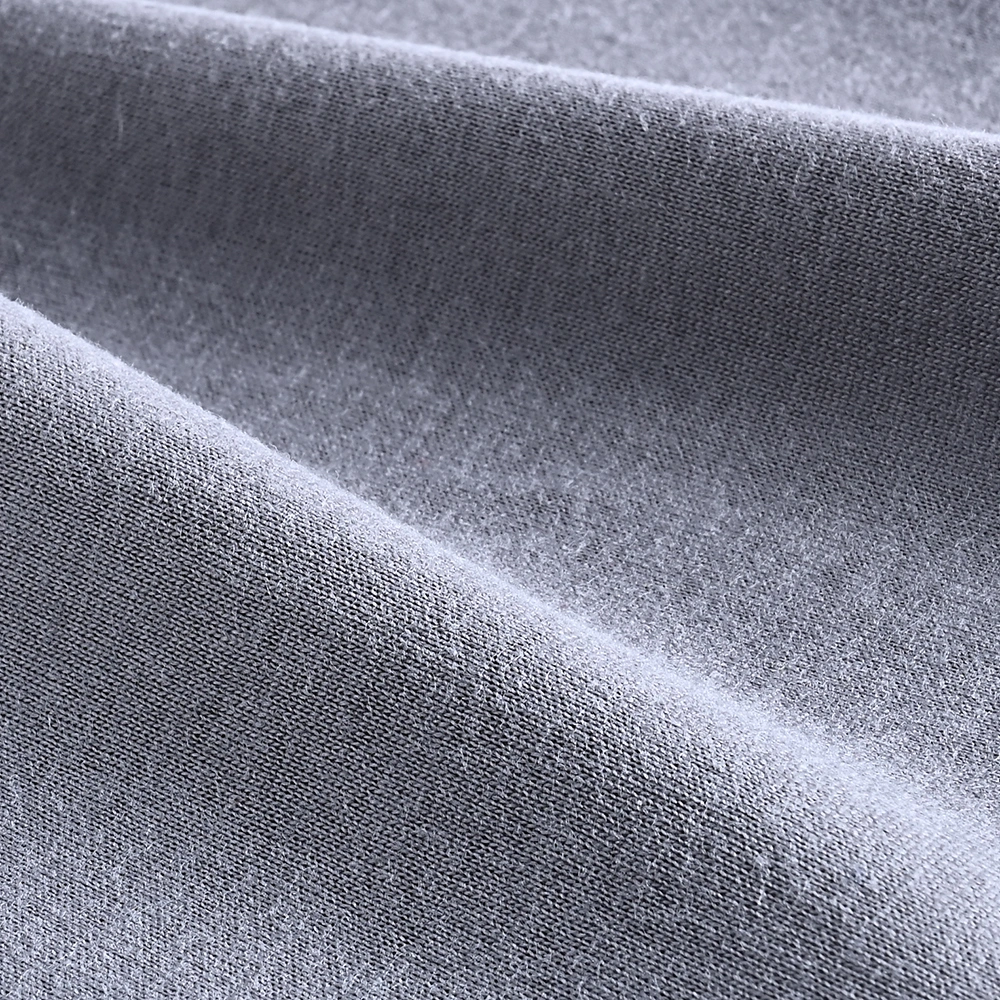

100% Cotton FR Fleece

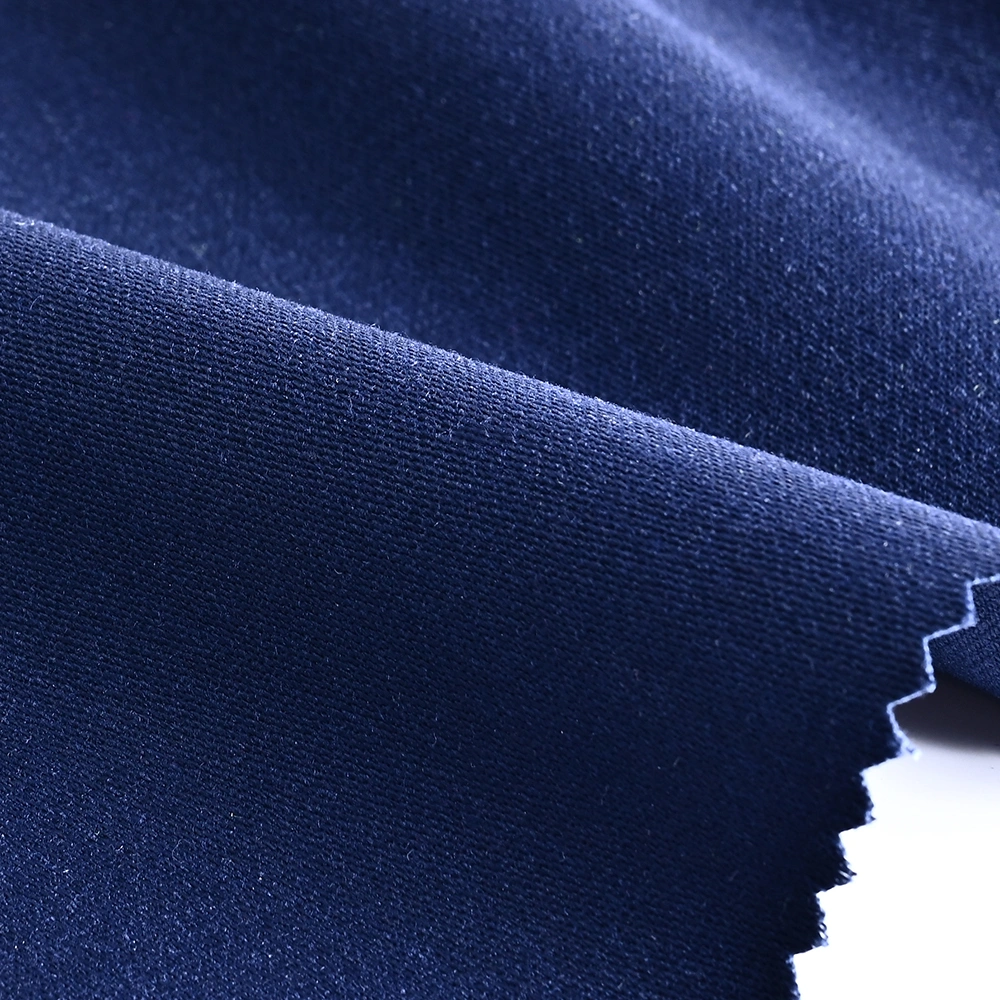

100% Cotton FR Jersey

100% Cotton FR Rib 2x2

100 Cotton FR Satin

100% Cotton FR Yarn Dyed Fabric

Chemical Treatment of Fabrics

The chemical treatment of fabrics is a critical process for enhancing their fire-resistant properties. This involves applying a fire retardant coating to the fabric, which significantly reduces its flammability. The treatment process can be used on various fabrics, including cotton, polyester, and nylon, making it a versatile solution for different applications. Typically, a chemical solution is applied to the fabric, which is then dried to achieve the desired level of fire resistance. The type of chemical used and the method of application can vary depending on the fabric and the required fire resistance. This process ensures that even materials that are not inherently flame retardant can provide effective protection against fire, making them suitable for use in high-risk environments.

Emergency Response

Firefighters and emergency responders depend on personal protective equipment that can withstand severe hazards. MH FR fabrics provide robust flame resistance and heat protection, effectively blocking flames and thermal radiation during rescue operations, thus preventing burn injuries. Engineered for both safety and mobility, these textiles maintain breathability and flexibility, reducing fatigue during high-intensity emergencies, and also minimize smoke production during fires.

Key Advantages:

-

High resistance to flames and elevated temperatures

-

Abrasion and tear-resistant for longevity in harsh conditions

-

Comfortable fit to support extended use and mobility

Certifications:

MH’s fabrics for emergency response comply with ISO 9001 Quality Management, ISO 14001 Environmental Management, and OHSAS 18001 Occupational Health and Safety Management standards. These certifications validate product quality, worker safety, and environmental sustainability.

Oil and Gas Industry

Workers in oil and gas face inherent risks from open flames, high temperatures, and combustible substances. These risks are particularly prevalent in industrial environments where stringent flammability standards are essential. MH flame retardant fabrics are primarily designed to provide a reliable barrier against fire hazards and feature anti-static properties to further reduce risk. These fabrics perform well on oil rigs, drilling platforms, and in refineries, supporting safety initiatives across the sector.

Key Advantages:

-

Superior protection against high temperatures and direct flame

-

Integrated anti-static properties to limit spark generation

-

Durable and comfortable construction for long shifts

Certifications:

MH oil and gas solutions are UL certified for fire and electrical protection and carry the OEKO-TEX® Standard 100 seal, confirming that textiles are free from harmful substances for safe, long-term skin contact.

Metallurgical Industry Protection

Metallurgical environments present dangers from molten metal, sparks, and continual high temperatures. The smooth surface of MH flame retardant fabrics allows molten materials to easily slide off, enhancing protection. MH flame retardant fabrics, reinforced with heat-resistant treatments, prevent burns and maintain performance under sustained use. The material resists splashes of molten metal and can withstand wear from handling heavy equipment. When combined with fire-resistant underwear and outer garments, these fabrics provide comprehensive protection against flash fire and electrostatic discharge (ESD).

Key Advantages:

-

Advanced heat insulation and flame protection

-

Strong resistance to sparks, molten metal, and high-pressure environments

-

Enhanced comfort and breathability despite extreme temperatures

Certifications:

Available fabrics are backed by ISO 9001 and OHSAS 18001 certifications for quality and occupational safety. OEKO-TEX® Standard 100 ensures safe skin contact and suitability for prolonged use in metallurgical operations.

Electrical Industry Protection

High-voltage maintenance and facility operation place workers at risk of electrical fire and heat exposure. The cal value of MH FR fabrics indicates their arc thermal protective value (ATPV), providing essential protection against thermal risks. MH flame retardant fabrics mitigate these hazards with superior resistance to flames and thermal events, while anti-static options lessen incidents caused by electrostatic discharge. These fire retardant fabrics meet related safety standards, ensuring they are suitable for use in demanding industrial conditions. Lightweight construction supports comfort and performance for ongoing tasks.

Key Advantages:

-

Excellent protection from electrical faults and high-temperature incidents

-

Anti-static fabrics reduce the risk of electrical fires

-

Lightweight and comfortable for demanding operational settings

Certifications:

Electrically rated fabrics are UL certified, with ISO 14001 certification underlining MH’s commitment to environmental responsibility.

Benefits of Flame Retardant Fabrics

Fire retardant fabrics offer numerous benefits, making them an invaluable asset in enhancing safety and protection. One of the primary advantages is their ability to reduce the risk of fire, protecting both people and property from potential harm. These fabrics are designed to be durable and long-lasting, capable of withstanding the rigors of use and cleaning without compromising their fire-resistant properties. This durability translates to economic benefits, as it minimizes the need for frequent replacements and repairs. Additionally, fire retardant fabrics contribute to environmental sustainability by reducing the overall impact of fires, which can cause significant damage and waste. By providing a reliable and effective barrier against fire, fire retardant fabrics play a crucial role in improving safety and reducing the economic and environmental costs associated with fires.

Sustainability of Flame Retardant Fabrics

The sustainability of fire retardant fabrics is an important consideration, as the environmental and health impacts of chemical treatments can vary. However, many modern fire retardant fabrics are designed with sustainability in mind, using materials and production methods that minimize negative impacts. Some fire retardant fabrics are made from recycled materials, helping to reduce waste and promote environmental responsibility. Additionally, manufacturers are increasingly adopting environmentally friendly chemical treatments, such as those based on natural materials like plants and minerals. These advancements ensure that flame retardant fabrics not only provide effective protection but also align with sustainable practices. Consumers should look for fabrics that are made with sustainable materials and production methods to ensure they are making environmentally responsible choices.

Global Recognition & Certifications

MH’s fire retardant fabrics meet or exceed industry standards, including:

-

ISO 9001 (Quality Management)

-

ISO 14001 (Environmental Management)

-

OHSAS 18001 (Occupational Health and Safety)

-

UL Certification (Fire and Electrical Safety)

-

OEKO-TEX® Standard 100 (Textile Safety and Skin Compatibility)

Compliance with various flammability standards and codes, such as NFPA 701, is crucial to ensure safety in environments where fire risk is a concern.

These certifications demonstrate MH’s dedication to product quality, regulatory compliance, and worker well-being. European standard certifications further validate the global recognition of MH’s commitment to safety and quality.

Conclusion

MH fire retardant fabrics set the standard for safety, comfort, and compliance in high-risk industries. Customer satisfaction is paramount, and MH ensures that all fabrics meet the highest safety specifications. Covering applications in emergency response, oil and gas, metallurgy, and electrical work, MH fabrics help organizations protect their workforce while supporting operational efficiency and regulatory requirements. These standards are crucial across the country, reflecting the importance of adhering to British Standards and other regional certifications. Companies that select MH flame retardant fabrics make a proactive investment in workplace safety, ensuring both legal compliance and the well-being of their teams.

Are you ready to strengthen your workwear with proven, certified protection? Contact MH today to discover how our flame retardant fabrics can be tailored to your sector’s needs. Ensure your workforce has the protection it deserves.![]()